Transforming battery housing into outdoor panels for Volkswagen with Novelis' closed-loop innovation

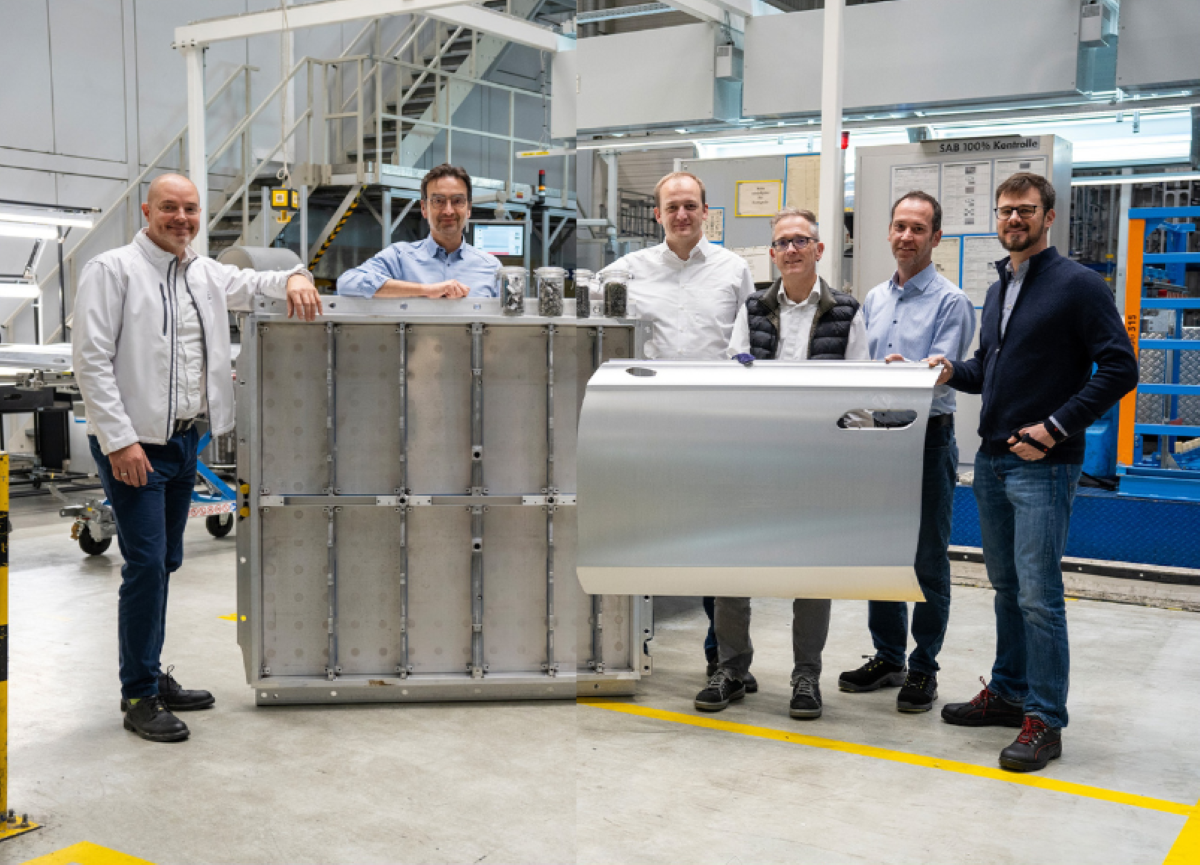

Volkswagen Group's Centre of Excellence Battery and Volkswagen Emden's Press Shop have closed the material loop for aluminium in battery housings for the first time in a groundbreaking pilot project.

Image Source: Volkswagen Linkedln page

Image Source: Volkswagen Linkedln page

Novelis & Volkswagen Group

In collaboration with Novelis, a global leader in aluminium recycling, aluminium from MEB pre-series battery cases undergo shredding, sorting, and alloy identification. The material is then transformed into coils and repurposed for new components, such as the outer door panel of the Volkswagen ID.7.

Novelis is proud to collaborate with Volkswagen Group on this groundbreaking initiative, showcasing the potential of aluminium recycling. By transforming battery housings into high-quality flat-rolled aluminium for new car components like outer door panels, the company is advancing sustainable electric mobility while reinforcing the commitment to the circular economy.

The aluminium loop is a closed-loop system designed for collecting, sorting, and recycling aluminium, ensuring continuous reuse. This process enhances the sustainability of aluminium products by minimizing waste and maximizing resource efficiency.

"This project promotes sustainable electric mobility. Along with a trusted external partner, we achieved a best practice example for the circular economy," said Viktor Enne, Project Manager of Recycling Technologies, Processes & Projects.

Other closed-loop initiatives by Novelis

- Novelis took part in Audi's MaterialLoop project, a pilot initiative focused on advancing end-of-life vehicle recycling. This collaborative effort, involving 15 partners from across the automotive value chain, is aimed to deepen industry knowledge on implementing a circular economy for vehicles. Audi's pilot project focused on dismantling and separating 100 vehicles to recover valuable materials, including aluminium, steel, glass, and plastics. As the world's leading aluminium recycler, Novelis brought its expertise in aluminium and alloy recycling, which is essential to the automotive industry.

- Novelis, the global leader in aluminium rolling and recycling, announced on May 28 that it will supply a sustainable, lightweight aluminium body sheet for the all-new Nissan Qashqai SUV. Novelis will also establish a closed-loop recycling system in Europe as part of this collaboration. The aluminium body sheet will be used in the Qashqai's hoods and doors, helping to reduce weight and improve fuel efficiency.

- In 2019, Novelis partnered with Volvo Cars to implement a closed-loop recycling system. Through this collaboration, Volvo's production scrap was collected and recycled, reducing reliance on primary aluminium and lowering the CO₂ footprint of the aluminium sheet supplied to Volvo by 78%. This system ensured that production scrap remained within the value chain, continuously transformed into high-quality aluminium products without degradation.

Recycled aluminium is vital to the future of sustainable mobility. A well-designed closed-loop and end-of-life recycling program ensures that like alloys remain separated, a crucial factor in maintaining the performance standards of automotive materials. To achieve this, advanced aluminium scrap segregation and sorting technologies are pivotal in any successful recycling initiative. These processes enable the collection and transformation of scrap aluminium into new vehicle components by refining alloy families and keeping them distinct. Maintaining alloy purity allows materials to be reused in their original applications, preserving value and reducing the need for primary metal input. This, in turn, facilitates the production of high-quality recycled aluminium coils.

News Source - Linkedln page of Volkswagon Group

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)