A Comprehensive Analysis of Bauxite Residue - Red Mud

This report offers a comprehensive analysis that promises to reshape the landscape of bauxite residue management.

Aluminium, a favoured metal across numerous manufacturing sectors, presents unique challenges during production. One such challenge is the industrial waste generated during bauxite processing into alumina through the Bayer process, which is called red mud. This waste is currently a matter of concern and an urgent issue in the aluminium industry, requiring an understanding to ensure its impact is minimised.

However, interestingly, despite being hazardous, red mud holds a promising potential for the industry. Its heavy toxic metal elements and high alkalinity, which can damage soil and life forms when disposed of, also make it a fascinating by-product for innovative utilisation in the cement, steel, ceramics, and agricultural sectors.

AL Circle has thus come up with a meticulously compiled, industry-focused report "A comprehensive analysis of Bauxite Residue - Red Mud," which addresses both the challenges and opportunities of the by-products. This report has all the necessary information to understand and manage red mud effectively, ensuring you are well-prepared to tackle its complexities.

This report is particularly in light of increased red mud generation due to steadily growing alumina production, touchingupon all the complexities associated with red mud, such as its chemical composition, disposal practices, and environmental impacts. All these concerns need a thorough understanding to alleviate the adverse effects and advocate its benefits. Hence, the report also sheds light on potential utilisations of red mud in various industrial sectors.

Before you explore the benefits and challenges of red mud, it is essential to know that every tonne of alumina production generates around 1.25 tonnes of red mud. In 2023, red mud generation across the world was around 177.25 million tonnes, which raised concerns for its storage and disposal. Due to the high content of toxic minerals and hazardous materials, red mud poses several risks, including soil and water resource contamination. Recycling aluminium is certainly a way to avoid excessive red mud generation and its adverse effects, but the need for primary metal is also undeniable.

So, delve into the opportunities that our report presents for red mud and also discover how companies are adopting various methods to reduce the detrimental effects of red mud by reducing liquid content and the presence of high amount of soda or by switching from wet storage to dry storage methodology.

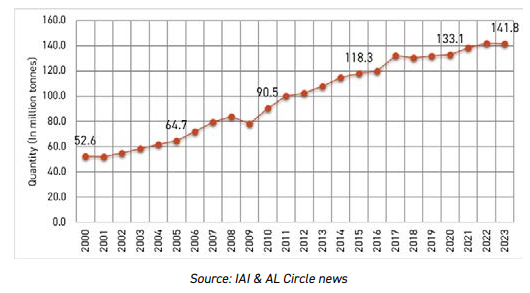

In this report, you will also learn about the region-wise production of bauxite and alumina to assess the world's highest red mud generation areas. In 2023, 177.25 million tonnes of red mud was generated against 141.8 million tonnes of alumina production. The alumina production growth of 4.61 per cent GAGR from 2000 to 2023 also implies a spectacular rise in red mud generation during the given timeframe.

Alumina production trend from 2000 to 2023 (million tonnes)

How will it benefit you?

Stay ahead: By gaining the latest insights into the most innovative utilisations and applications of red mud in various manufacturing sectors, you can position yourself as a leader in the industry.

Cross-industry network: You will learn about the industries beyond aluminium that are working with this hazardous waste to pave the path for sustainability.

Informed decision: All this information will help you make an informed decision about the emerging opportunities in the red mud landscape.

Methodology

1) Scope – This report essentially covers - (I) Bauxite reserves and mining trends, (2013 – 2023), (II) Mineralogical composition of tropical bauxite and bauxite type geographic distribution, (III) World alumina production trend, (1974 – 2023), (IV) Key alumina producers by production & capacity, (V) Red mud generation & various alumina industry parameters, (VI) Year wise red mud generation, (1974 – 2023), Red mud generation across major countries like China, Australia, India, Brazil, Russia, UAE, etc., (VII) Types of red mud generated in China (%), (VIII) Application where red mud is utilised, (IX) Methods of managing red mud, (X) Neutralisation of red mud (remediation/rehabilitation).

2) Data Collection

- Advanced Internet Research: In-depth research has been performed for data collection. The primary sources include associations, such as the Australian Aluminium Association, United States Geological Survey (USGS), and International Aluminium Institute (IAI), government databases, published articles, white papers, conference presentations, journals like the Indian Journal of Engineering & Materials Science, and annual reports of companies like Vedanta, Hindalco, Hydro, Chinalco, Alcoa, Rusal, Rio Tinto and others.

- Review of the database: The curated database, with the input of subject matter experts, includes facts and figures from AL Circle (www.alcircle.com) news, blogs, interviews, and press releases.

3) Research

- The facts and figures in this report are derived from comprehensive market research, which includes collecting and examining historical data, reviewing research reports, consulting government publications, and calculating compound annual growth rates.

- Analytical software tools like MS Excel and Looker Studio have been used to visualise and interpret data.

- Evaluated reports & trade data sourced from the International Aluminium Institute (IAI), International Trade Council, Central Pollution Control Board, Ministry of Mines, and sustainability reports of various companies around the world in the upstream sector.

Frequently asked questions