ALUMINIUM 2018 trade fair to present the potential of aluminium recycling

Today, aluminium scrap is already one of the most economically valuable secondary raw materials. Around 20 per cent of the world's aluminium requirements are covered by post-consumer scrap. ALUMINIUM - the world's largest industry event - will present the latest developments and potential of aluminium recycling from 9 to 11 October in Düsseldorf.

Significance of recycling is increasing in a time of shrinking raw material reserves and scarce, and above all expensive, energy. The advantage is there are no qualitative differences between alloys made from the primary metal and those made from recycled aluminium.

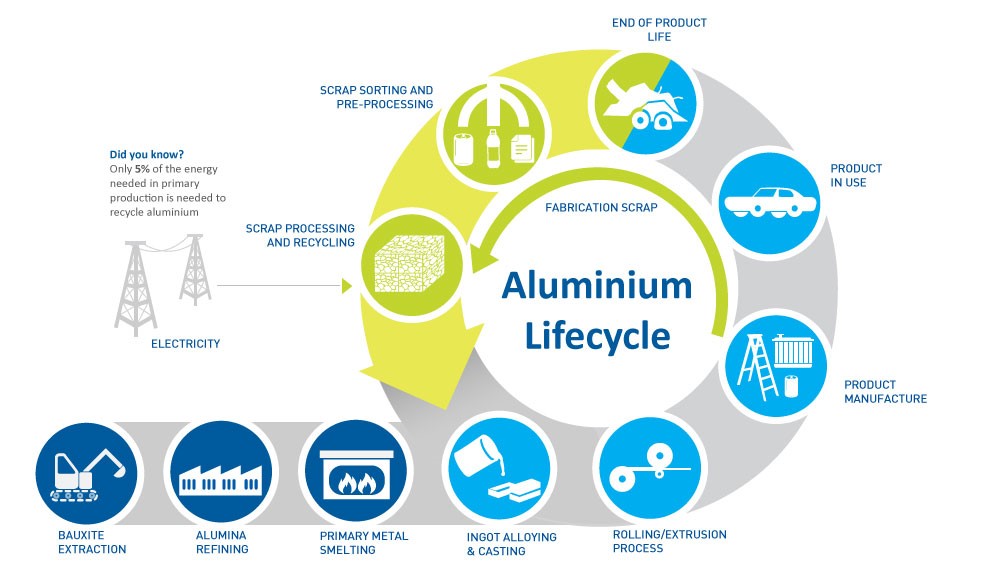

{alcircleadd}Scrap supply is the bottleneck for the aluminium material cycle, since aluminium is used mostly in products with long lives, e.g. in construction applications like windows or in cars. Global aluminium industry had already been running its material through a closed-loop cycle of metal production, processing, use, recycling and recovery. This has been prevalent in automotive and construction applications – with recycling rates of about 95 per cent – and now for applications in packaging like food and beverage cans. Recycling rates of more than 80 per cent have been reached in this segment in Germany, and the rate is rising in the EU area, as well.

Graphic Courtesy: Hulamin

The aluminium industry continues to work on filling existing gaps in the circular economy. In order to recycle the raw material even more intensively in Germany, German aluminium companies are investing in the expansion of their recycling capacities, drawing on ultra-modern plant engineering technology.

Post-consumer scrap covers 20 per cent of aluminium demand

According to estimates by the International Aluminium Institute, about 17 million tonnes of post-consumer scrap accumulated worldwide in 2016. This volume will increase to about 21 million tonnes in 2020. Today, about 20 per cent of aluminium demand is covered by old scrap. Another source of raw materials besides old scrap is new scrap, generated in the production of semi-finished goods, in casting foundries, or from the mechanical processing of semi-finished goods and other products. Increasing aluminium demand from the transport and construction sector leads to higher demand for semi-finished goods, which results in a higher volume of scrap. Companies are taking measures to reduce scrap generation and recycle the scrap.

Recovering and recycling aluminium scrap conserves resources and makes an important contribution to limiting the rise of greenhouse gases. The industry goal is to keep end-of-life aluminium products in the reusable material cycle by leveraging appropriate collection systems, including end-of-life vehicle recycling, proper upgrading and dismantling, and deposit systems and/or recycling bins. The pool of aluminium scrap will grow exponentially, toughening the requirements for processing and sorting, on the one hand, and the metal trade on the other.

From 9 to 11 October, the ALUMINIUM trade fair in Düsseldorf will present the latest developments and potential of light metal recycling. The world's largest industry event for the aluminium industry will dedicate its own exhibition space to the subject of recycling. A total of around 1,000 exhibitors and 27,000 visitors from 100 nations are expected.

Global players, specialists and young innovative companies will present the complete range of the industry, from aluminium production to machines and plants for processing, semi-finished products, products for the application industries and recycling. In addition to that, the fair will also focus on processes and product innovations for the most important aluminium application industries: Automotive, mechanical engineering, construction, aerospace, electronics, packaging and rail transport.

The fair is organised by Reed Exhibitions with the support of the German Aluminium Industry Association (GDA) and the European Aluminium Industry Association.

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)