Decline in aluminium can recycling linked to youth drinking less?

The aluminium industry must cut its emissions intensity by 30 per cent by 2030 and 9 per cent by 2050 compared to 2022 levels to align with the International Aluminum Institute’s (IAI) 1.5-degree benchmark. To achieve this, absolute carbon dioxide (CO2) emissions for aluminium (both primary and secondary) need to be reduced to 810 million tonnes in 2030 and further to 53 million tonnes by 2050.

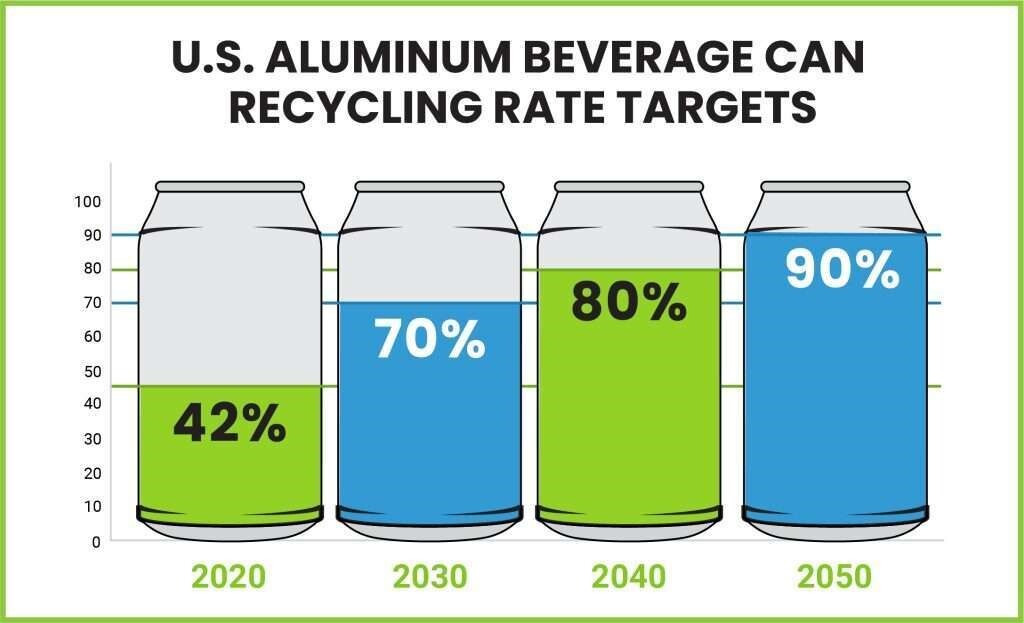

Image Source: Can Manufacturers Institute

Image Source: Can Manufacturers Institute

The industry has reduced emission intensity by 13.6 per cent from 2019 to 2023 which is primarily driven by improvements in reduced reliance on coal, increased secondary production and energy efficiencies. The absolute emission for aluminium (primary and secondary combined) was 1.13 gigatonne of CO2 e in 2019, decreasing to 1.12 gigatonne of CO2 e in 2023. Hydropower and renewable energy contribute to 39 per cent of the electricity used in smelting. Secondary aluminium, which requires significantly less energy, contributes to 36 per cent of total production.

Wisconsin statistics walk the opposite way

Despite the global emphasis on sustainability, Wisconsin faces declining aluminium recycling rates. A recent report from the Wisconsin Policy Forum reveals that facilities handling materials from local governments are receiving less aluminium recycling material. Between 2013 and 2022, aluminium container recycling fell by 16.4 per cent, or 1,800 tonnes. Local media attribute this drop to younger generations consuming less beer and alcoholic beverages, which traditionally come in aluminium cans.

Events

Events

e-Magazines

e-Magazines

Reports

Reports

This news is also available on our App 'AlCircle News' Android | iOS