AM feedstock novel aluminium wire sufficiently decreases heat treatment time

Situated in Melbourne, the Innovative Manufacturing Cooperative Research Centre (IMCRC), and AML3D Limited from Edinburgh, alongside Deakin University's Institute for Frontier Materials (IFM), Victoria, have come together to create a novel high-strength aluminium wire feedstock.

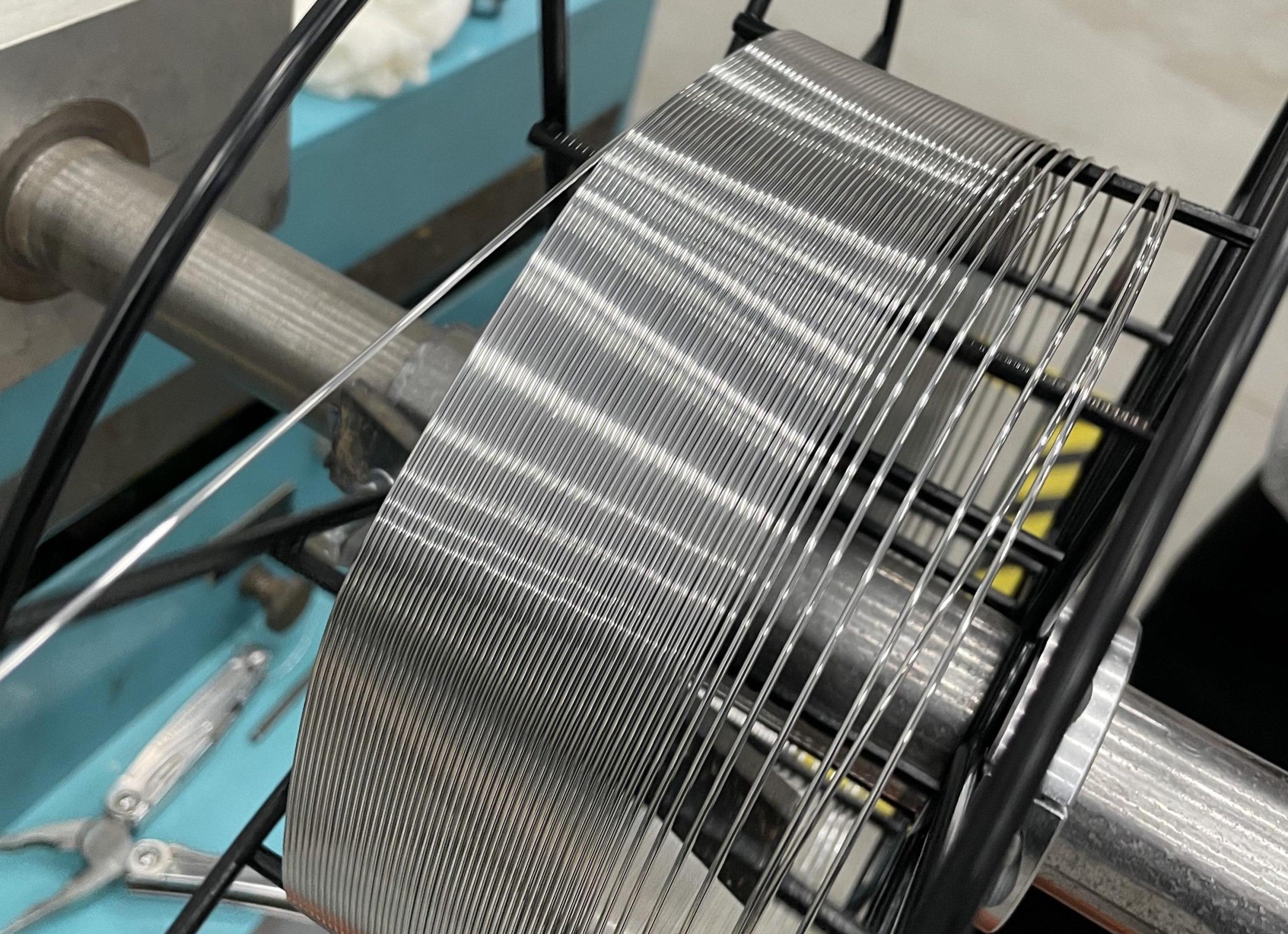

This feedstock would be compatible with Additive Manufacturing devices and suitable for welding technologies that exponentially reduce post-manufacturing heat treatment duration.

The latest wire feedstock is the outcome of a research project that commenced in 2021 due to the aggravating need for high-strength aluminium wire for Additive Manufacturing by AML3D. It was crucial for the company to develop such an alloy that disregards heat treatment after manufacturing is accomplished.

The Executive Director and Chief Technical Officer of ALM3D, Andy Sales, explained: "Our patented Wire Additive Manufacturing (WAM) [a form of wire-based Directed Energy Deposition] 3D metal printing process can produce medium to large objects. However, the aluminium alloys we currently use require up to 24 hours of heat treatment to reach optimum strength, which can be costly and creates some logistical challenges."

"Through our partnership with IFM and IMCRC, we've developed a cost-effective, high-strength aluminium alloy wire that requires just thirty minutes of heat treatment once printed. When used with our WAM technology, this wire has the potential to create additional applications across industries like shipbuilding and aviation, further disrupting traditional manufacturing processes," Andy added to his statement.

The Senior Research Fellow at IFM, Thomas Dorin, remarked: "We were pleased to work with AML3D and IMCRC on this ambitious project, which encompassed over twenty different compositions and iterations. Our chosen alloy, a mixture of aluminium, magnesium and scandium, has recently been patented, and we've also commenced commercial production."

The project's next phase will involve additive manufacturing products to demonstrate the wire's potential applications." We'll then work with AML3D to show shipbuilders how they can print directly at the shipyard, which is an effective way to reduce material waste and streamline logistics," Dorin narrated.

The CEO and Managing Director of IMCRC, David Chuter, elaborated: "We're pleased the project outcomes have solved a real-world challenge for AML3D and the 3D printing industry more broadly. By creating an alternative to traditional processes like subtractive manufacturing, AML3D has the potential to catalyse a step-change for industry and encourage the adoption of more innovative manufacturing techniques."

This news is also available on our App 'AlCircle News' Android | iOS