BrewDog, a Scottish drinks company, has committed itself to reduce its carbon footprint with the new construction of a green gas plant that will generate energy to produce more than 176 million pints of beer per year at the company’s Ellon production base in Scotland.

BrewDog claims that its new bio-energy plant worth £12 million can reduce carbon emissions by 7,500 tonnes per year when operating with its total capacity. During the second half of Thursday, June 16, the plant was revealed by BrewDog authorities.

Recycling is an indispensable part of the aluminium industry which is both viable and sensible economically, technically and ecologically. It also saves energy, as it only consumes 5 percent of the total energy required to generate aluminium from its ore, which means lesser carbon footprint on the earth.

This facility will act as the forerunner for BrewDog’s idea of a £50 million investment plan to curtail carbon emissions per hectolitre of beer by 35 per cent if compared with its former baseline in 2019.

BrewDog's director of sustainability, Sarah Warman explained: "We're not just here to make great beer - we're making great beer that doesn't cost the Earth. Our ambition is nothing short of making BrewDog beer the most planet-friendly beer on Earth, and we've taken giant strides towards that goal with our new bio-energy plant.”

The available organic waste materials in the brewing process will be the main fodder for the anaerobic digester of the plant, in turn generating ample green gas to run the company’s brewery. Eventually, the surplus gas will be available to power delivery vehicles, and the rest will be offered to the national gas grid.

The digester is another innovation by the company in addition to other initiatives by BrewDog to lower its carbon emissions ratio. For example, the company’s Australian brewery yields 16MWh of energy per month by using rooftop solar panels, also the US brewery is following the same path by installing solar energy cells for electricity generation.

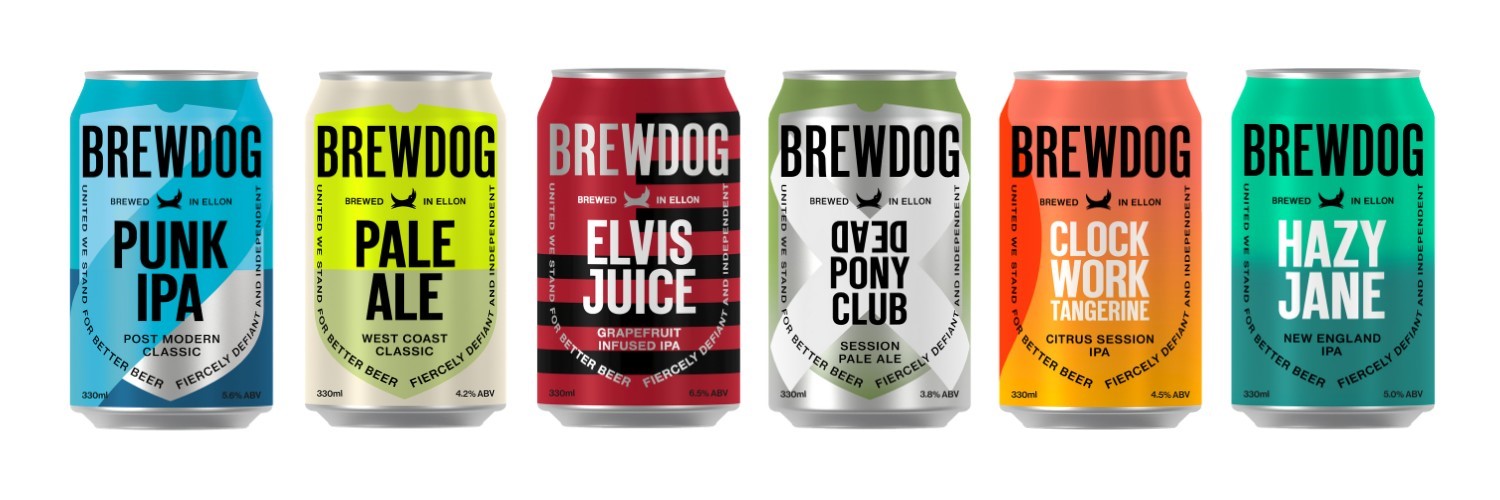

On the other hand, BrewDog's currently opened canning plant is ready to supply cans, featuring a 35 per cent lower carbon footprint than bottled beer. The can manufacturing unit is moving towards a day when all its products will have 100 per cent recycled aluminium.

BrewDog is optimistic about the anaerobic digester as it will help the company recycle most of its 200 million litres of wastewater discarded every year in the production method of beer.

In fact, in the later years, the company hopes to use the residual CO2 emitted by the digester for the successful carbonisation of its beer.

After it is fully active, the digester will generate almost 200 cubic metres of biomethane each hour, equal to at least 23,000 MWh of energy per year, ample to provide heat to more than 1,500 houses.

"Our number one sustainability goal is to reduce emissions, and we want to lead the way for the entire brewing industry,” Warman added.

Moreover, in addition to everything, BrewDog is supportive of the peatland restoration and tree planting projects near Aviemore to plant over 1.1 million trees over the 9,308 acres of Lost Forest land in the area.

Responses