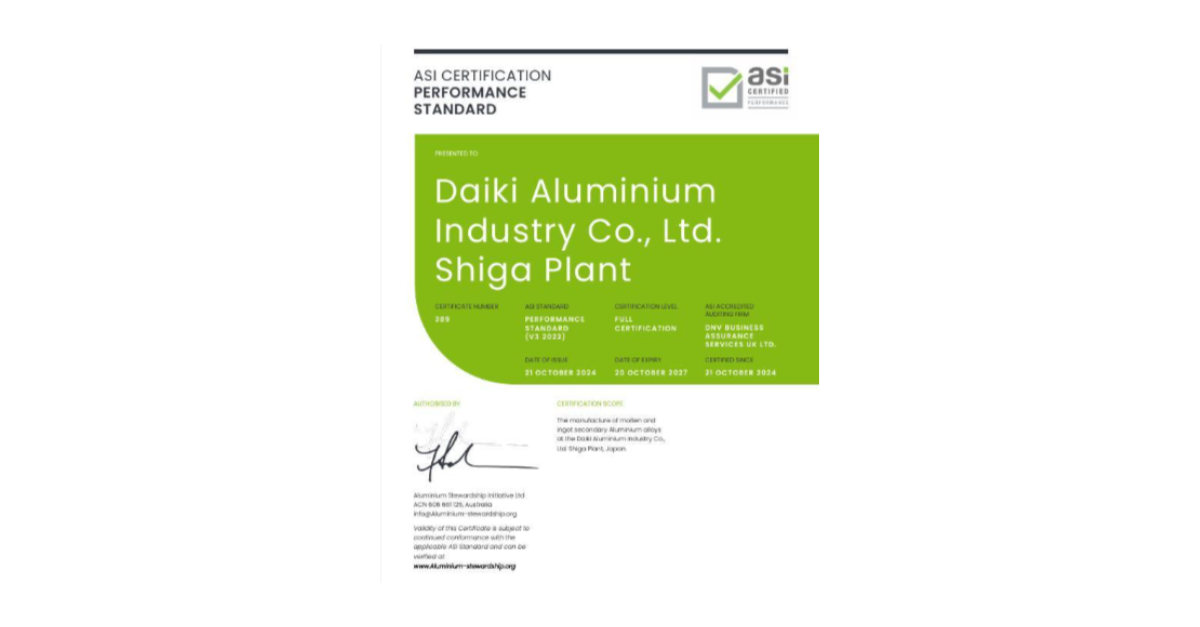

Daiki Aluminium achieves the ASI Performance Standard V3 Certification for its Shiga plant

Aluminium Stewardship Initiative (ASI), the global organisation known for setting industry standards and certification in the aluminium value chain, has recently announced the certification of Daiki Aluminium. The Japanese manufacturer, known for producing secondary aluminium alloys used in high-pressure die casting, casting, and rolling, has achieved the ASI Performance Standard V3 (2022) Certification. This certification applies to Daiki Aluminium's production of secondary aluminium alloys in both molten and ingot forms at its Shiga Plant.

Image Source: ASI

The Aluminium Stewardship Initiative (ASI) announced the certification, highlighting the facility's use of aluminium scraps as the primary raw material to produce recycled scrap ingots and recycled liquid metal. The Shiga Plant boasts an annual production capacity of approximately 38,500 metric tonnes and features advanced infrastructure, including three melting furnaces, two rotary furnaces, casting equipment, molten metal transport equipment, and raw material pretreatment systems.

The ASI Certification program, developed through extensive multi-stakeholder consultation, is the only comprehensive voluntary sustainability standard for the aluminium value chain. The ASI Performance Standard V3 (2022), launched in May 2022 after a multi-year revision process, encompasses 11 principles and 62 criteria across three key sustainability pillars: Environment, Social, and Governance. DNV Business Assurance Services UK Ltd conducted the independent third-party audit of Daiki Aluminium Industry Co., Ltd.

This news is also available on our App 'AlCircle News' Android | iOS