An international team of engineers has pioneered a scalable and innovative approach to fabricating topography-patterned aluminium surfaces, significantly enhancing liquid transport capabilities. These advancements hold great promise for critical applications, including electronics cooling, self-cleaning technologies, and anti-icing systems.

Image Source: research website

An important step in tailored surface engineering

The research, recently published in Langmuir, was a collaborative effort between Rice University and the University of Edinburgh under the Rice-Edinburgh Strategic Collaboration Awards program. It highlights the use of cost-efficient vinyl masking techniques to create surfaces with high-resolution wettability contrast, unlocking new potential for improving phase-change heat transfer technologies.

"This method represents an important step in tailored surface engineering. By enabling precise control over surface wettability and thermal properties, we are opening new doors for scalable manufacturing of advanced heat transfer surfaces," said Daniel J. Preston, assistant professor of mechanical engineering at Rice and a co-corresponding author of the paper, along with Geoff Wehmeyer, assistant professor of mechanical engineering at Rice, and Daniel Orejon from the University of Edinburgh.

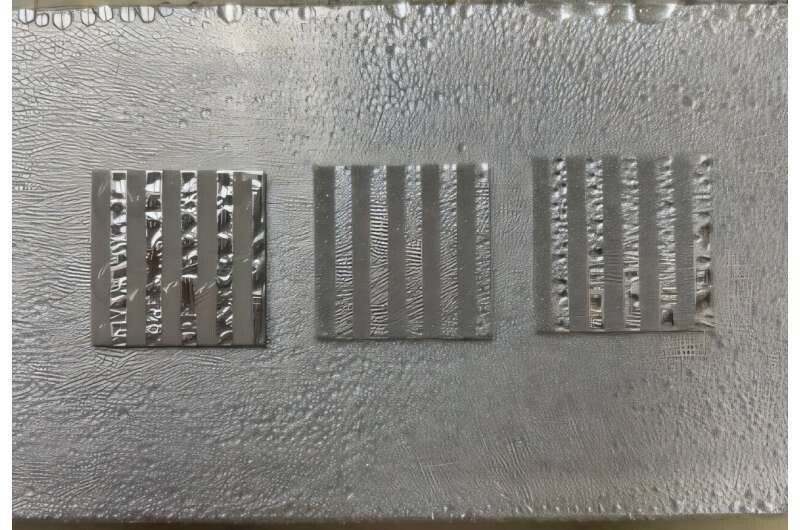

The research team has developed an innovative method that combines blade-cut vinyl masking with commercially available lacquer resin and scalable physical and chemical surface treatments to produce patterned aluminium surfaces. These surfaces demonstrate pronounced wettability contrasts, significantly enhancing droplet shedding during condensation. Featuring patterns as small as 1.5 mm, the technique enables a diverse range of wettability behaviours—from superhydrophobic to hydrophilic—depending on the specific treatment.

Research procedure

The research utilised a multi-step approach to develop and evaluate patterned aluminium surfaces. Polished aluminium substrates were first covered with vinyl masks, followed by a two-step etching process to create micro- and nanotextured regions. Advanced imaging techniques were employed to analyse the resolution of the patterns and their wettability properties.

"Aluminum is widely used in thermal management devices like heat exchangers due to its high conductivity, low density and low cost. Our method adds a new dimension to its functionality by integrating surface patterning that is both cost-effective and scalable, allowing engineers to fine-tune the condensation heat transfer. This work brought together expertise from Edinburgh and Rice to develop and characterise these advanced surfaces," added Wehmeyer.

Performance evaluation included condensation visualisation experiments, which confirmed improved droplet shedding on the patterned surfaces compared to uniform ones. Infrared thermography-based thermal emissivity mapping further revealed notable emissivity contrasts between smooth and textured areas, emphasising the potential of these surfaces for advanced thermal management applications.

The findings of the research

The findings hold significant promise for industries reliant on phase-change heat transfer, with applications in everyday technologies. In electronics cooling, improved droplet shedding minimises thermal resistance caused by large droplets during condensation, paving the way for innovative cooling strategies in data centre servers and other devices where efficient heat dissipation is essential to prevent overheating.

"Traditional methods like photolithography are typically expensive and limited to small areas. Our technique uses affordable, accessible materials to create intricate patterns on larger surfaces, making it suitable for industrial applications and a promising technique for designing next-generation condensers and heat exchangers," commented Preston.

Customised thermal emissivity patterns enhance heat dissipation in high-temperature environments, offering advantages for systems such as automotive engines and aerospace components. Moreover, superhydrophobic regions facilitate rapid water removal, preventing ice formation on critical surfaces like airplane wings, wind turbines, and power lines in freezing conditions. These advancements provide practical solutions to boost the performance and reliability of essential technologies used in daily life.

The lead authors of the study are Trevor Shimokusu, a Rice University mechanical engineering doctoral graduate and current faculty member at the University of Hawaii, and Hemish Thakkar, a Rice graduate with a double major in chemistry and mechanical engineering, now pursuing a doctoral degree at Princeton University.

Responses