First time Ronal Group produces wheels from 100% secondary aluminum for BMW

The world’s leading manufacturer and supplier of light alloy wheels for passenger cars and commercial vehicles, Ronal Group, has set itself the aim of a 50 per cent reduction in its manufacturing CO2 emissions by 2030 and CO2-neutral production of all its wheels by 2050 as part of its PLANBLUE sustainability plan.

With the production of the first light-alloy wheels built entirely of secondary aluminium for the new all-electric MINI Cooper SE Convertible, the German plant in Landau is taking the lead in this area.

The production of primary aluminium is an energy-intensive process that impacts the environment. The carbon balance sheet of the RONAL GROUP shows that 74 per cent of the CO2 generation is attributable to aluminium procurement. The company sourced 100 per cent of its aluminium from members of the Aluminum Steward Initiative (ASI), and 63 per cent of the aluminium it purchases is proven to be produced using renewable energy. The wheel manufacturer has also been ASI Performance Standard certified since September 2022.

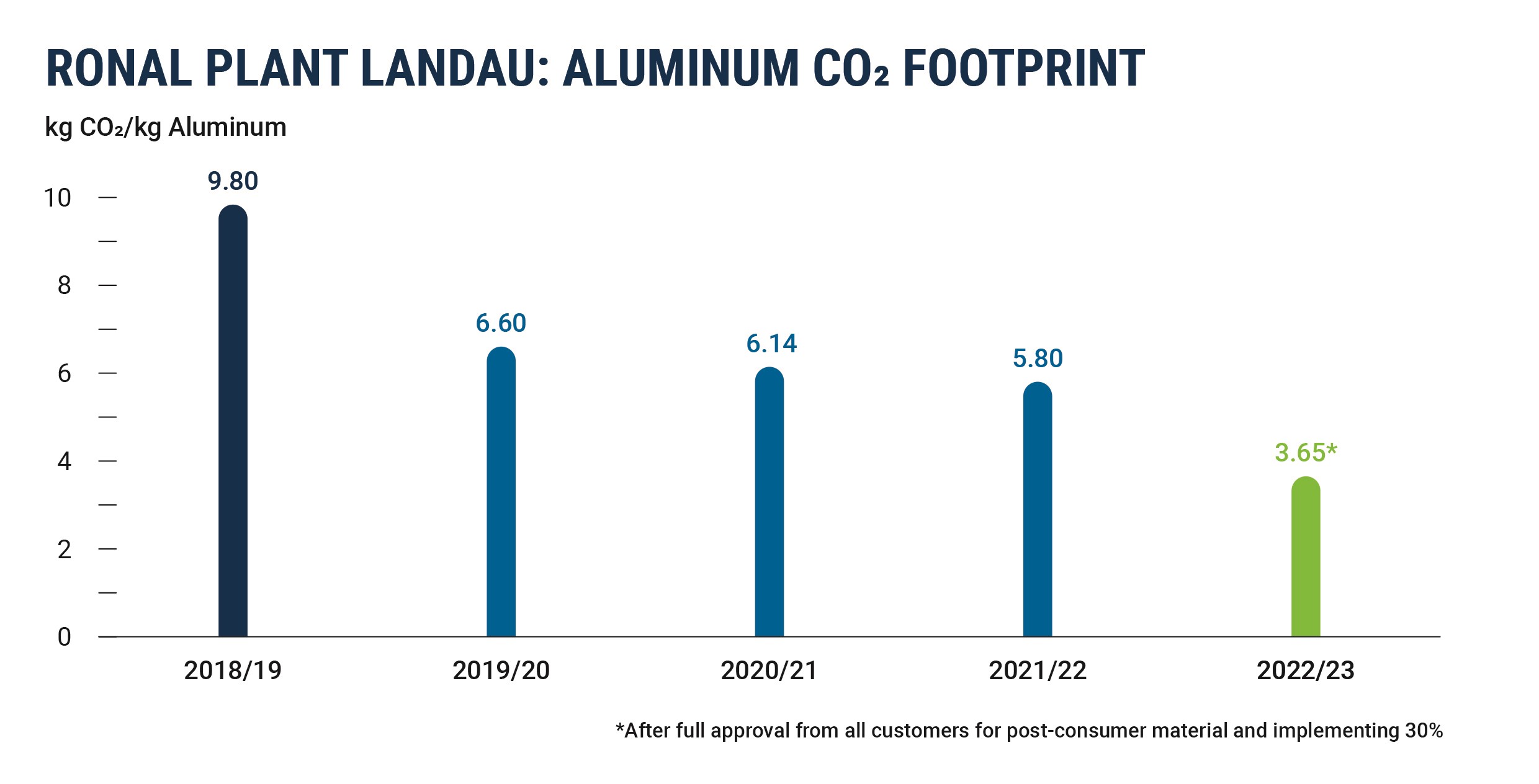

Furthermore, the Ronal Group has been working for years to expand its sustainable resources and increase the proportion of recycled materials in its manufacturing operations. This has been done so as to continuously reduce the company's ecological footprint. The RONAL GROUP production plant in Landau, Germany, intends to obtain approval from all its OEM customers for the use of secondary aluminium by mid-year, so as to halve its CO2 footprint by the end of the year.

In cooperation with the car manufacturer MINI, the Ronal Group has now produced the world's first light-alloy wheels made of 100 per cent secondary aluminium for use on a vehicle in series production. The new MINI Cooper SE Convertible is equipped with wheels made of 40 per cent pre-consumer and 60 per cent post-consumer material.

Pre-consumer scrap includes aluminium waste, such as chips generated in production, which must be processed in an intermediate step before being fed back into the smelting process. In order to reutilize them, they must be washed and dried.

The post-consumer aluminium is supplied by the company Eccomelt. The quality of this is the same as that of primary aluminium, and it currently exhibits the best CO2 footprint on the market. By using recycled material, the CO2e emissions in production can be reduced by up to 75 per cent. At the end of its life, the alloy wheel of the MINI Cooper SE Convertible can itself be recycled to make a new wheel.

The Ronal Group is also pursuing the idea of the circular economy – both in cooperation with its OEM customers and in developing its products for the aftermarket.

Martin Wyss, the Head of the RONAL-Re (RONAL Aluminum Wheel Recycling) project, said, "With the RONAL R70-blue, at the end of 2020, we already launched the first CO2-neutral wheel with recycled aluminium content on the market. It consists of a majority of pre-consumer and post-consumer material as well as primary aluminium produced from renewable energy sources.”

“The project was launched at Ronal Group in March 2021 and aims to replace as much primary aluminium as possible with recycled aluminium in wheel production by 2030.”

"We can conserve valuable resources by minimizing the use of primary materials and replacing them with recycled materials of equally high quality. We demonstrate the feasibility of this in terms of the circular economy both with our RONAL R70-blue and with the wheels made of 100 per cent secondary aluminium that we produce for the MINI Cooper SE Convertible."

This news is also available on our App 'AlCircle News' Android | iOS