Friction Stir Welding: An innovative technology for Aluminium welding

Friction Stir Welding (FSW) is a promising technology for assembly aluminium parts since 1995. All aluminium alloys can be welded including high-strength alloys (2000, 6000 and 7000 series). This method is also used and very popular for assembly dissimilar materials, such as aluminium - copper, aluminium - steel, Al foundry parts. However, FSW remains a technology reserved for high added value applications involving expensive equipment.

StirWeld, a French young start-up firm has developed an FSW head that fits existing machining centres or NC machine tool. This makes FSW accessible by all the manufacturing companies, especially SMEs, as most of the job-shops are already equipped with the NC machine tool. This new welding device requires only a few hours of training and becomes a true hybrid tool combining welding and machining. Moreover, this approach can save time as the components can be welded and machined in the same place, with the same machine. The system is suitable for small or large workpieces, with weld thickness lower than 15 mm, which is sufficient for most applications.

By this way, StirWeld reduces drastically the cost of FSW technology while proposing performances identical to a special machine or FSW robot (force control, quality recording). StirWeld innovation enables companies to optimize their machines and to implement new know-how for their customers.

The advantages of FSW head for NC machine tool:

- Low investment cost: compared to special machines or robotic FSW stations.

- Adaptability: despite the lack of machining centre standard, StirWeld head can adapt all the NC machine tool.

- Ease of use and installation: after the first set-up, the user can mount and dismount the head within a few minutes, easily changing from welding to machining and vice versa.

Today, Cap Group in Lisieux, France, is the first French subcontractor to offer this technology to its aeronautical and space customers. The automotive sector is also interested in the innovation: PSA and Saint-Jean Industries having welcomed this FSW head on their NC machine tools for test campaigns.

FSW technology

In 1995, a new welding technique is invented by The Welding Institute (TWI): Friction Stir Welding (FSW). Since 2015, the TWI patent falls in the public domain, opening great opportunities for the development of FSW technology.

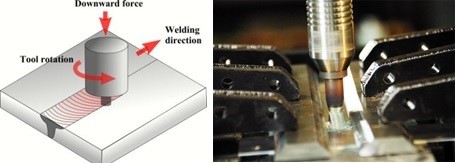

FSW Principle:

Step 1: The FSW tool consists of a shoulder to heat the material by friction and a pin to stir the parts together.

Step 2: The parts have clamped either edge to edge (butt welding) or by overlapping (lap welding).

Step 3: The tool is rotated (speed from 400 to 1800 rpm) and then dips vertically into the material.

Step 4: After a temperature stabilization phase (between 1 to 5 seconds), the tool moves along the weld seam (constant speed of 200 to 3000 mm / min depending on the nature and thickness of the components).

Step 5: During movement, a controlled force (3 kN to 18 kN) is applied to the FSW tool. The heat generated by the friction makes the material softer and the tool stirs the parts together. The welding operation is carried out in a solid-state without material fusion.

Step 6: At the end of the weld, the tool rises vertically leaving a hole. This hole is often seen as a defect; however, many solutions exist to solve this drawback.

FSW advantages:

Cost Benefits:

- Reduction of post-welding inspection

- Few consumables, no material input, no surface preparation

- Welding is carried out in an NC machine tool limiting investment

- Possible rental of the FSW head to limit the investment

Advantages of goods:

- Welding of all aluminium alloys (1xxx, 2xxx, 4xxx, 5xxx, 6xxx, 7xxx)

- Mechanical resistances close to the base material

- Al-Si: easy welding of aluminium foundry, including die casting

- No leakage: water, acid, or air

- Excellent thermal and electrical conduction.

Process advantages:

- Responding to the shortage of qualified welders.

- The weld is invisible on the backside and requires small machining on the welding side to remove it if necessary.

- Replacement of brazing, TIG, MIG or FE welding.

- Cold welding: minimal distortion of welded parts.

- No spar, no smoke.

Customer benefits:

- Already democratize in aeronautics, automotive, space, railway and naval sectors

- Existing welding standard: ISO 25239

Innovation: FSW on NC machine tool

Since 1995, Friction Stir Welding (FSW) is a promising technology for assembly aluminium parts. StirWeld invention uses an NC machine tool for FSW. This innovation reduces drastically the investment cost to access to FSW while offering performances identical to a special FSW machine. This optimizes the job-shop machines and diversifies their technology offer to customers. Today, several companies have trusted this technology: Cap Group in Lisieux, French leading subcontractor in FSW, PSA and Saint-Jean Industries for automotive applications.

Advantages of FSW on NC machine centre:

- Low investment cost: compared to special machines or robotic FSW stations.

- Adaptability: Despite the lack of machining centre standard, StirWeld head can adapt all the NC machine tool.

- Ease of use and installation: after the first set-up, the user can mount and dismount the head within a few minutes, easily changing from welding to machining and vice versa.

FSW applications on NC machine tool

Aluminium profile joining: Extrusion of aluminium parts is limited to a width of 500 mm (technical and economic problems beyond this size). The solution: FSW makes it possible to produce components whose dimensions are not achievable in a single extrusion. Examples of application sectors: automotive, railway, naval, aeronautics.

Replacement of traditional assemblies (riveting, MIG, bonding): The most resistant aluminium alloys are not weldable with conventional technologies because of their chemical composition (2000 and 7000 series). These alloys are currently assembled by screwing, sticking or riveting. Many companies would like to replace these processes to reduce manufacturing costs while increasing the mechanical strength of assemblies. FSW results in fast and high strength assembly of all aluminium alloys. Examples of application sectors: aerospace, civil engineering (bridges). FSW is one of the most significant advances in the manufacturing of NASA Space shuttle tanks, as well as in Ariane and Space X rockets.

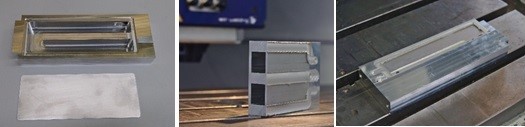

Manufacture of heat sinks or other sealed systems: An active heat sink is an aluminium component in which a fluid circulates cooling electronic components. Conventional assembly technologies (screwing, brazing or FE welding) can lead to problems of quality (leakage, mechanical resistance), design (complex geometries are not possible) and manufacturing (time-consuming set-up). FSW leads to perfectly sealed welds and resistant to high pressures. Moreover, FSW is very easy to implement, even for small batches and complex geometries. Examples of sectors of application: aeronautics, railway, wind turbine, military.

Welding of casted parts: Aluminium cast parts are difficult or not weldable with conventional processes (degassing of casted aluminium). FSW allows the welding of aluminium castings, even die-casted pieces, due to the solid-state. Examples of application sectors: automotive, electronic casings. Several car manufacturers have adopted FSW to optimize the vehicle weight while not affecting the mechanical characteristics. The automotive industry already uses FSW to product wheels (Saint Jean Industries), battery casing (Renault, Tesla) and heat exchangers. Below, cooling fins on an electronic housing: 2 FSW welds to ensure the thermal conductivity.

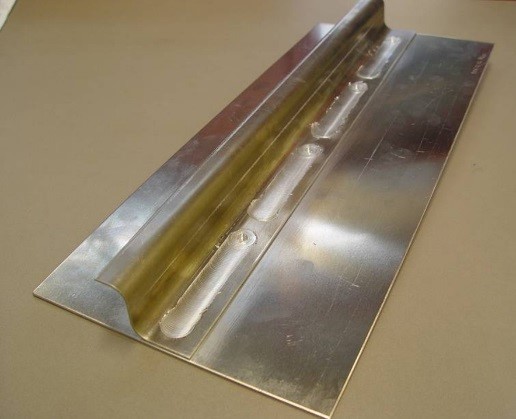

Reduction of raw material: many mechanical parts are machined from a massive block of aluminium where up to 90% of material is removed. Many companies would like to reduce their cost of raw material and their machining time. The solution: part welding by FSW to get a preform as close as possible to the final shape. Examples of application sectors: aeronautics, military, nuclear, space.

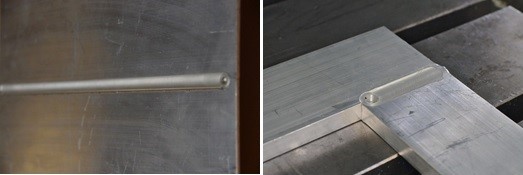

Replacement of spot welding: conventional resistance welding requires a finishing operation for ornamental applications. This operation is time-consuming and tedious requiring qualified operators. FSW by lap welding results in the no-affected backside and eliminates grinding. Examples of application sectors: sheet job-shop, aeronautics.

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)