Hulamin’s cold mill upgrade aims to resolve tight edge issues in aluminium strips

Primetals Technologies has successfully signed the Final Acceptance Certificate (FAC) with Hulamin, a leading aluminium producer, following the installation and commissioning of advanced hot edge inductors for the cold mill rolling line (S5) in Pietermaritzburg, South Africa. This upgrade targets eliminating tight edge issues in aluminium strips encountered during high-speed rolling, significantly enhancing product quality.

Image Source: Primetals Technologies

Image Source: Primetals Technologies

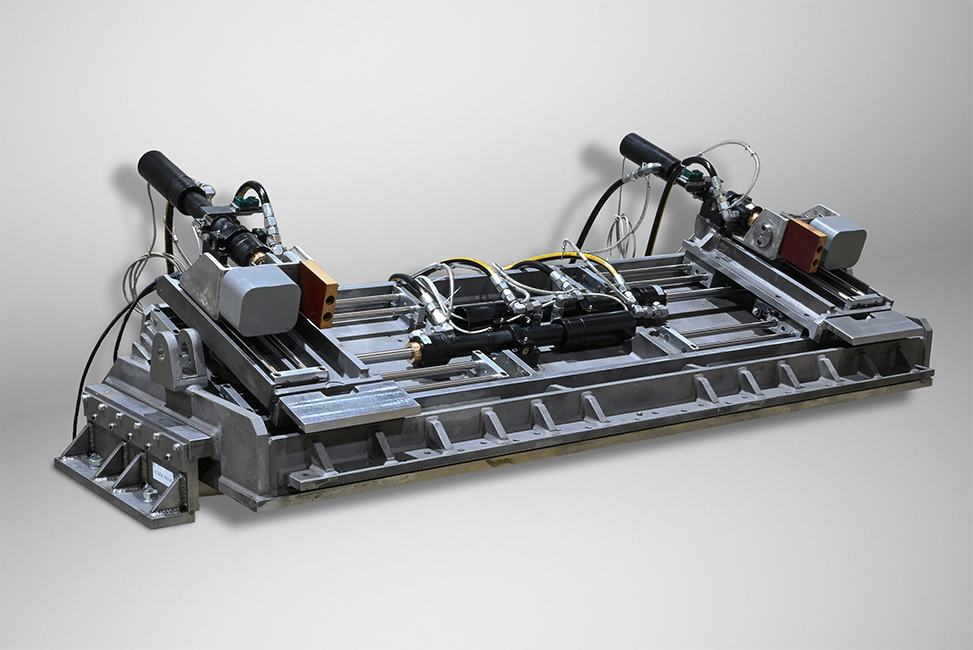

The newly installed moving induction heating head assemblies are strategically positioned on the exit side of the mill, beneath the exit delivery table. These assemblies, placed just outside the strip width near the roll surface, effectively mitigate thermal camber, addressing the tight edge challenges during high-speed rolling operations.

“Hulamin is extremely pleased with the implementation and the resulting improvement in product quality. Following this success, discussions are ongoing about implementing similar systems on additional mill lines at their site in Pietermaritzburg”, said Calvin Coetzee, Senior Fluids Engineer at Primetals Technologies.

The hot edge inductors have effectively resolved the tight edge issues by applying targeted heat to the work roll at the strip edges. This localized heating causes the roll to expand, alleviating tight edges and ensuring improved control over the strip edge shape. Hulamin has reported significant enhancements in the on-line strip shape performance and continues to optimize and refine the application of these actuators as part of its rolling program.

Improved Product Quality

Primetals Technologies has completed the design, procurement, manufacturing, supply, and commissioning of an advanced inductor system within 18 months. The moving induction heating head assembly is strategically installed on the exit side of the mill, beneath the exit delivery table. Positioned near the roll surface and just outside the strip width, these assemblies effectively mitigate thermal camber, the primary cause of tight edge issues during high-speed rolling.

The hot edge inductors expand the roll at the strip edges by delivering targeted heat to the work roll edges, resolving tight edge problems. This enhancement has significantly improved control over the strip edge shape, allowing Hulamin to achieve superior product quality and maximise cold mill capacity.

About the collaboration

As part of a comprehensive upgrade to Hulamin's cold rolling system, the introduction of hot edge inductors has delivered promising results. The aluminium producer has reported significant improvements in on-line strip shape performance and is actively working to optimise and refine the use of these advanced actuators within its rolling program.

The close collaboration between the Hulamin and Primetals Technologies teams, from initial planning to final testing, has been instrumental in the system's success. Hulamin's mill operations team has fully integrated the system into daily operations, leveraging it to enhance mill productivity and ensure consistent shape performance.

This news is also available on our App 'AlCircle News' Android | iOS