Hydro invests NOK 1 billion in two sustainable projects: A new extrusion press and recycling capacity expansion

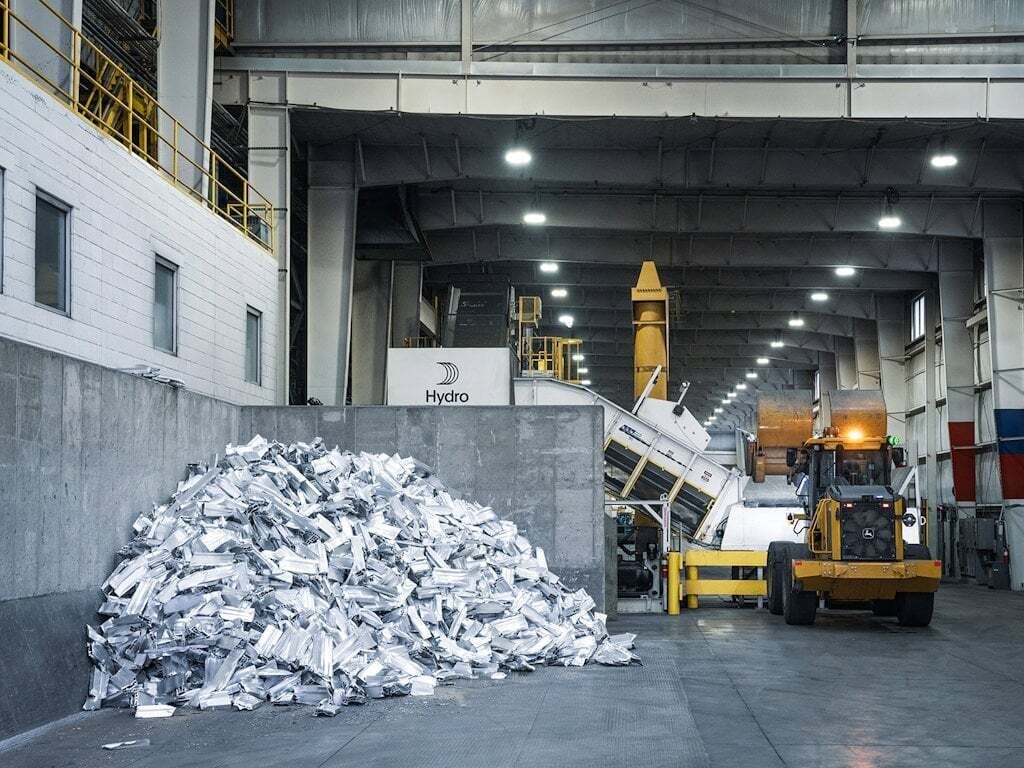

Hydro introduces a 12-inch indirect extrusion press, invalidating two older presses in Cressona, Pennsylvania, where the capacity of the recycling facility has also been expanded to an additional 50,000 tonnes.

The NOK 1 billion investment goes into taking forward the company's effort to create more efficient and modern operations in North America. A part of these projects shall present the most extensive recycling facilities of Hydro to date, with a capacity of 2,70,000 tonnes per year.

"With these investments, we continue the development of the Cressona plant as a key part of Hydro Extrusions in North America. The increased efficiency and the ability to deliver recycled aluminium with a lower carbon footprint to our North American customers caters to the growing demand for more sustainable products," states Jeff Lehman, Business Unit President, Extrusion North America.

From a 1942 built facility to North America's largest aluminium extrusion establishment, the U.S. Government site has come a long way with at present 1,100 employees, three extrusion ingot casting units, 11 extrusion presses, extensive fabrication capabilities and a distribution warehouse all in 15 hectares (149,000 square meters) under its roof.

Fact check of Hydro's new projects

A 12-inch indirect extrusion press of 3000-tonne capacity has the technical craftmanship to mobilise advanced monitoring systems and automation, enabling it to be categorised under North America's transportation, distribution, and industrial sectors' key server.

Indirect extrusion presses being found lesser as compared to direct extrusion presses, Hydro's only indirect extrusion presses are installed in North America.

Alongside this, the enhanced recycling facility can support post-consumption aluminium scrap recycling into a closed-loop system. Recycled aluminium products have a lower carbon footprint and are highly considered viable in heavy-duty industries prioritising sustainability in their supply chains.

Hydro's investment comes as the demand for sustainability and low carbon emission rises more than ever in aluminium production, promising to meet the holistic expectation of North America's automation, distribution and construction market.

This news is also available on our App 'AlCircle News' Android | iOS

.gif/0/0)