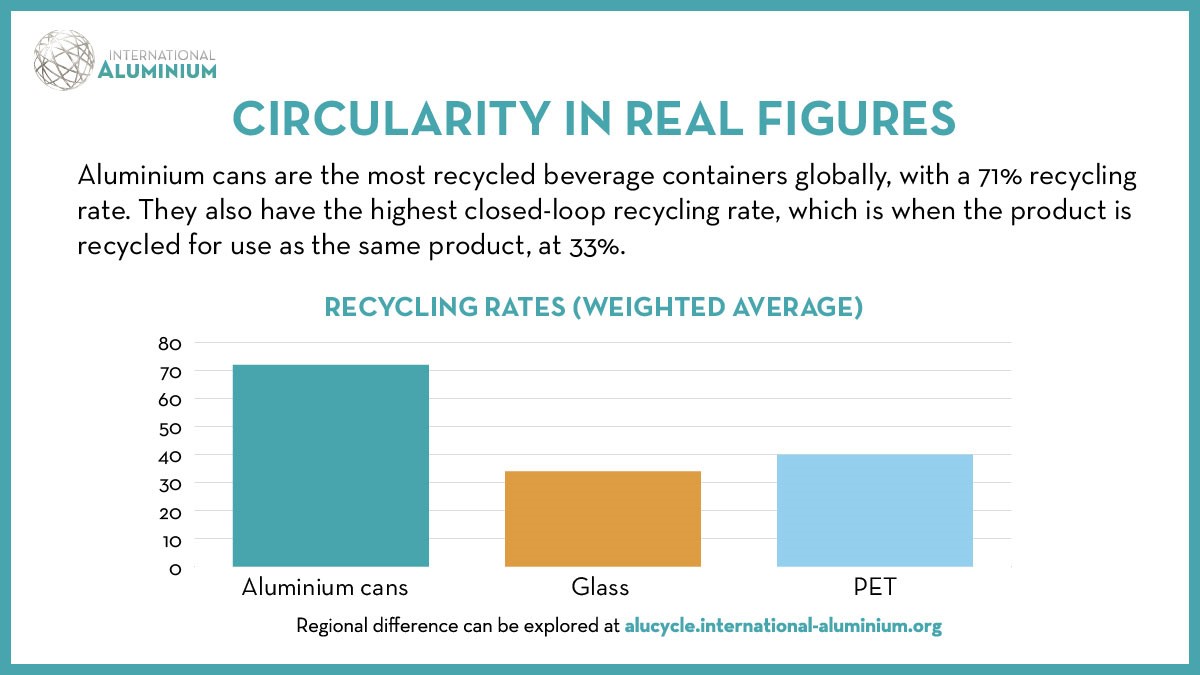

IAI affirms aluminium cans best support circular economy: Recycling rate of 71% outperforms glass & PET bottles

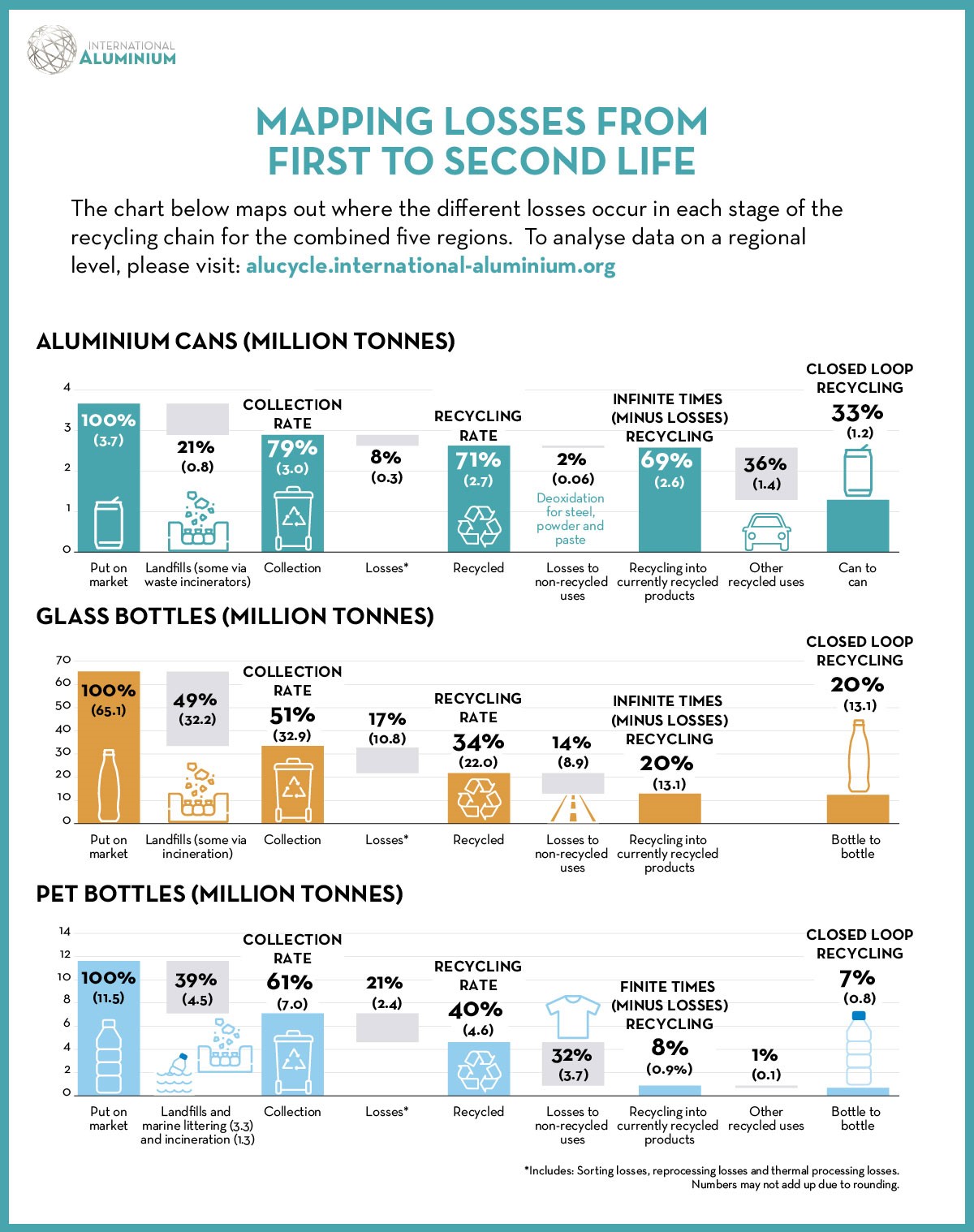

The first comprehensive research report on recycling value chain, launched by the International Aluminium Institute (IAI), shows that aluminium cans best support a circular economy than glass or plastic (PET) bottles. This claim has been established after studying through collection, sorting, reprocessing and thermal processing, closed-loop recycling, and open-loop recycling in five regions – Brazil, China, Europe, Japan, and the United States. Study shows that out of 3.7 million tonnes of aluminium cans in the market, about 0.8 million tonnes or 21 per cent end up in landfills, whereas 32.2 million tonnes or 49 per cent of 65.1 million tonnes of glass bottles and 4.5 million tonnes or 39 per cent of 11.5 million tonnes of plastic bottles go to the landfill.

This indicates that the collection rate of aluminium cans is much higher than glass or plastic bottles. About 3 million tonnes or 79 per cent of aluminium cans are collected for recycling in those five regions, as compared with 51 per cent and 61 per cent of collection rates of glass and PET bottles.

The recycling rate of aluminium cans stands at 71 per cent, while that of glass and plastic bottles comes in at 34 per cent and 40 per cent, respectively. The study also reveals that closed-loop recycling of aluminium cans is 33 per cent of the total cans, much higher than 20 per cent and 7 per cent of glass bottles and PET bottles.

Ramon Arratia, Vice President Global Public Affairs at Ball Corporation, noted that “While no drinks container has achieved its full circularity potential yet, aluminium outperforms glass and plastics (PET) at all stages of the waste management system. Today, aluminium cans are the most recycled beverage containers globally. Once the aluminium can is collected from the consumer, it has an unrivalled sorting, reprocessing and remelting efficiency rate of 90% compared with glass (67%) and PET (66%). On this basis, aluminium can be described as a material of choice for a circular economy. This is especially important when we look at the carbon reduction potential of recycling.”

Andrew Wood, Group Executive Strategy & Business Development at Alumina Limited, said: “The number of aluminium cans collected at the end of their life is about 18% higher than PET bottles and 28% higher than glass. A greater proportion of PET and one-way glass bottles end up in landfills or waterways because they are not collected. In a decarbonising world, this is likely to contribute to higher demand for both recycled and primary aluminium.”

Marlen Bertram, IAI’s Director, Scenarios & Forecasts, said: “As the Institute celebrates its 50th anniversary this year, we have been reflecting on our organisation’s long history of data collection, analysis and modelling. Aluminium is one of the most recyclable materials on the planet and the IAI is campaigning to ensure end-of-life products are returned into the recycling loop given the economic and environmental benefits of the metal in our global economy. Comparing recycling rates of different materials is meaningless if you don’t know how the rate is measured and into what products the material is recycled back to. This study is the first public study that comprehensively analyses the extent of recycling and losses of three beverage containers in different regions. By increasing the precision of identifying where major losses occur, the study could provide solutions to improving the rate of recycling for all materials. We are clearly in a new era in circularity transparency.”

Emilio Braghi, EVP Novelis & President Novelis Europe, said: “Collection and sorting systems are essential to increasing circularity and to unlocking the full potential of infinitely recyclable materials. We need a policy framework that incentivises true recycling and circular systems, where at the end of their life, beverage containers are recycled again and again – without loss to quality. Aluminium is perfectly suited for multiple product-to-product recycling. We need to move our thinking from waste to valuable resource – reusing existing material to produce new packaging and thereby saving precious natural resources, energy, and lowering emissions.”

This news is also available on our App 'AlCircle News' Android | iOS