Sustainable solutions: Technologies decarbonising aluminium production

Aluminium stands as an indispensable pillar in our modern world, driving the pulse of our global economy with its unparalleled versatility and sustainability. From powering aeroplanes to speeding up cars, its unique properties propel industries forward and shape the products we rely on daily, from beverage cans to smartphones.

In the dynamic realm of aluminium production, the quest for sustainability is gaining momentum amidst significant challenges. The traditional Hall-Héroult cell technology, vital yet beset by external electricity supply issues, is at a crossroads. Rising demand, set to surge nearly 40% by 2030, underscores the urgent need for greener production methods.

Innovation, however, remains constrained by the durability and affordability of essential materials, crucial for advancing concepts like drained cathodes and inert anodes. Despite incremental gains in energy efficiency, progress has been deliberate, emphasising the industry's journey towards sustainability.

Amidst these challenges, breakthrough technologies and initiatives are emerging, promising to revolutionise aluminium production and curb emissions.

Tackling aluminium's emissions for a greener future

Aluminium is a versatile marvel across industries, prized for its lightweight prowess, exceptional strength-to-weight ratio, and ability to conduct electricity and heat.

Aluminium's allure deepens as it emerges as a cornerstone of sustainable practices and a linchpin in the global shift towards cleaner energy solutions. Its 100% recyclability makes it a key player in the transition. From renewable energy infrastructure to electric vehicle components, aluminium is indispensable.

Yet, its production casts a shadow: As noted by the International Energy Agency, it accounts for approximately 3% of the world's direct industrial CO2 emissions. While strides are being made to reduce its carbon footprint, accelerated progress is imperative for achieving net-zero emissions by 2050.

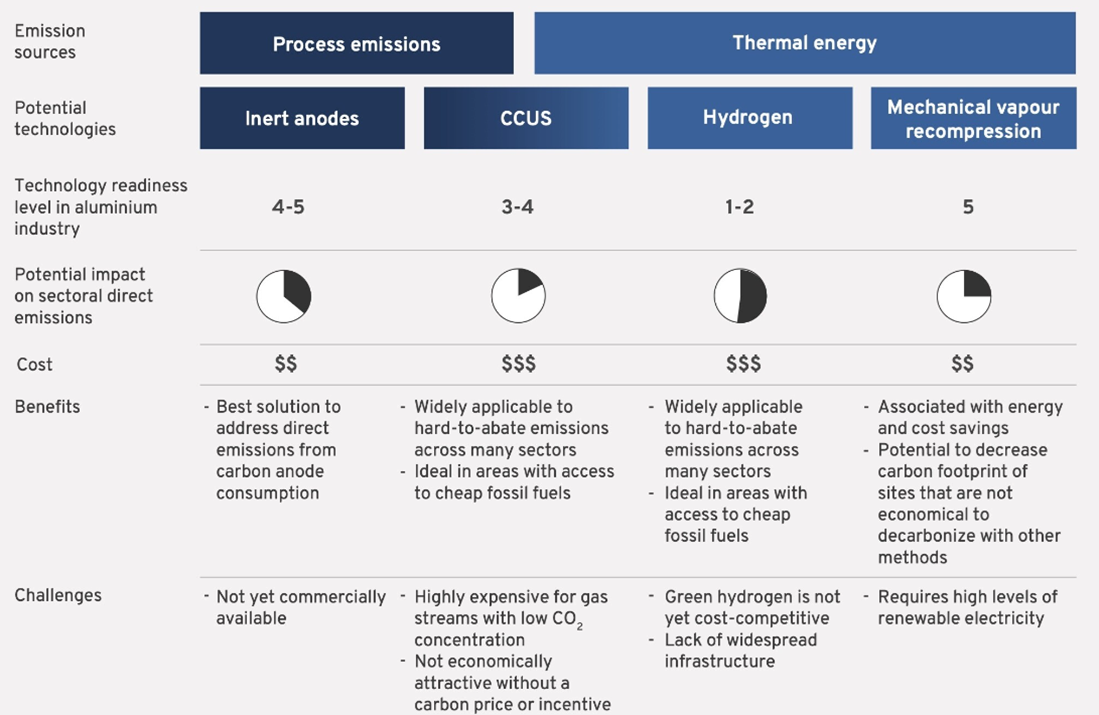

Decarbonisation mechanism to address direct emissions in the aluminium sector

Source: World Economic Forum

In the quest for decarbonisation, collaboration is the keystone that supports transformative change. As partnerships and commitments drive the industry's progress toward greener horizons, technological innovation stands ready to spearhead a wave of breakthroughs. These advancements promise to slash emissions and usher in a new era of sustainable industry practices.

- Sustainable technology transforming aluminium smelting

The Norwegian aluminium giant and renewable energy firm Hydro was honoured at the 2023 UN Climate Change Conference in the United Arab Emirates for its groundbreaking advancements in green aluminium technology. Hydro's proprietary innovation, known as HalZero, aims to fully decarbonise aluminium smelting—a potential game-changer in the industry since the invention of the Hall-Héroult process in 1886.

Unlike traditional methods that emit CO2 during the electrolysis stage, HalZero technology maintains carbon and chlorine in a closed loop, eliminating CO2 emissions and releasing only oxygen. Hydro targets industrial-scale production by 2030 and plans to produce the first aluminium using this revolutionary technology by 2025.

- Ultra-pure recycled aluminium

Researchers in the United States have announced a groundbreaking technological innovation designed to remove metallic impurities from recycled aluminium melts. This advancement opens the door for more diverse applications, including use in electric vehicle manufacturing. Although specific details remain confidential, the technology has already been licensed to a domestic recycled aluminium producer.

This development is part of a more extensive research and development initiative supported by Remade, a 170-member public-private partnership partially funded by the United States Department of Energy. The ongoing R&D project, titled ‘Selective Recovery of Elements from Molten Aluminium Alloys,’ is led by Subodh Das, CEO of Phinix. The project aims to develop technologies that enhance the quality and increase the usage of recycled aluminium in US manufacturing.

This innovative technology holds the potential to revolutionize the aluminium industry by lowering energy costs, boosting profits, and greatly enhancing the value of recycled aluminium. Although aluminium is one of the most recycled materials globally, there's still ample opportunity to elevate its recycling rates, reduce costs, and improve its recyclability and sustainability.

- Hydrogen as a sustainable substitute for fossil fuels

In June 2021, Rio Tinto embarked on a pioneering partnership with the Australian Renewable Energy Agency (ARENA) to explore the potential of hydrogen as a sustainable alternative to natural gas in alumina refining. This innovative $1.2 million feasibility study, co-funded with a $580,000 grant from ARENA, focuses on integrating clean hydrogen into the calcination process at the Yarwun alumina refinery in Gladstone.

At Rio Tinto's Bundoora Technical Development Centre in Melbourne, renowned for its cutting-edge research, efforts are expanding to include hydrogen technologies. This initiative aims to significantly curb emissions during the energy-intensive refining phase of aluminium production. By embracing these advanced clean energy solutions, Rio Tinto is forging ahead in its quest to lead the charge towards producing environmentally friendly, green aluminium.

- Conclusion

Producing high-purity aluminium from smelters to enhance the recyclability of scrap is a strategic move, expanding the spectrum of reusable materials. Flexibility in primary aluminium production allows for on-demand high-purity output, thus increasing available scrap for recycling and aligning with waste reduction goals.

Addressing environmental impacts, such as carbon dioxide and high-leverage PFC emissions from carbon anode use, remains pivotal. The industry's unwavering commitment to sustainability is evident in its focus on minimising PFC emissions through effectively controlling anode effects, a critical sustainability initiative. Energy efficiency in the energy-intensive Hall Héroult process is another key priority, with incremental gains promising substantial cost savings, emissions reductions, and broader benefits.

Despite technical constraints in existing reduction cells, the industry's dedication to innovation is unwavering. Advancements in sensors, controls, and materials offer pathways to enhance energy efficiency, metal quality, and environmental performance. However, these advancements face challenges in accuracy and applicability. The industry's quest for revolutionary improvements is hindered by the lack of commercially viable alternatives to the Bayer and Hall Héroult processes, impeding significant gains in cost-effectiveness and efficiency.

Improved collaboration among industry, government, and academia is crucial. Optimising these partnerships can accelerate technology development, fostering innovation and driving sustainable advancements in aluminium production.

Source: World Economic Forum, Recycling International, Rio Tinto

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)