As a result, Fourier transform infrared (FTIR) spectroscopy is a technique that can be used for measuring and reporting greenhouse gas (GHG) inventories and monitoring and managing PFC emissions to drive process improvements and emission reductions.

Image Source: ISCOBA PDF

The aluminium industry is striving to reduce and eliminate greenhouse gas emissions. In response, the International Aluminium Institute (IAI) launched an initiative encouraging its members to track and publicly report their emission reduction efforts and progress as part of COP28 in 2023.

These potent greenhouse gases significantly contribute to global warming due to their high efficiency in trapping infrared radiation. Thirteen major aluminium producers have endorsed this initiative, publishing their greenhouse gas reduction targets across various sources. These targets are categorised by emission scopes, with goals set for 2030 and some companies aiming for net-zero emissions by 2050.

Functionality of the FTIR method

The FTIR method relies on the infrared absorption of chemical molecules when exposed to light within a spectrometer. It records light intensity responses across a wavelength range, producing a graph known as a spectrum. Infrared absorption occurs due to changes in the rotational and vibrational energy of molecular bonds in gas compounds.

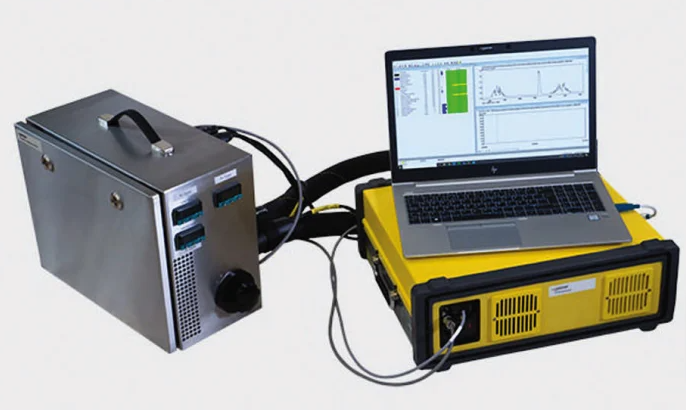

An FTIR instrument comprises a light source, a gas cell compartment, a detector, and signal-processing electronics that convert the optical signal into a spectrum, displaying absorbance values across a wavelength range. Selecting the appropriate FTIR instrument configuration is crucial for accurately detecting low concentrations of PFC emissions.

FTIR spectroscopy - key advantages

The key advantage of FTIR spectroscopy is its ability to measure nearly all gases present in smelter pot exhaust simultaneously, as it scans the entire infrared spectrum at once. This enables the detection and quantification of various emissions, including sulfur dioxide (SO₂), carbon monoxide (CO), carbon dioxide (CO₂), and carbonyl sulfide (COS). Additionally, spectral data can be reprocessed to verify CF₄ and C₂F₆ emissions across different wavelength ranges, ensuring accurate monitoring and analysis.

FTIR spectroscopy requires extractive sampling with filters to prevent instrument intensity degradation and protect internal optics from corrosion. Additionally, periodic maintenance may be necessary during measurement campaigns. While FTIR is a reliable technique, it can experience signal drift over time and must be precisely calibrated, particularly in the low parts-per-billion (ppb) range.

Why the industry should invest in FTIR technology

The aluminium industry faces the challenge of reducing or eliminating PFC emissions. Smelters can mitigate high-voltage PFC emissions by minimising their frequency and duration while also working to prevent or reduce low-voltage PFC emissions. To achieve this, smelters should employ advanced instruments that not only measure emissions but also predict the conditions leading to their formation.

Investing in FTIR technology and sampling equipment can yield significant returns through process optimisations that lower PFC emissions. Smelters can improve overall pot performance and increase metal production by preventing low-voltage PFC generation during anode changes, enhancing feeding processes, and maintaining pot stability.

Responses