Top five aluminium busbar manufacturers in the world

The global busbar market size is estimated to reach US$16.55 billion growing at a 5.48% CAGR from 2016 through 2021, reveals data in a recent market report. Busbars are critical electrical components used in power generation, commercial, metals and mining, oil and gas, chemicals and other industries. Increase in worldwide energy consumption due to rapid industrialization and modernization, and cost and operational benefits of busbars are expected to drive the market for busbar. Aluminium busbar (segment) by virtue of its low weight and cost-effectiveness is going to grow at the fastest CAGR replacing copper in a number of applications.

Following are the top five aluminium busbar manufacturers in the world. Please note the listing here is dynamic and based on the vendors’ product line depth and market reach. The ranking may change if a different of factors is taken into consideration.

1. ABB Ltd. (Switzerland)

ABB's MDY busduct system is the automation giant's solution for power transmission from the transformer to low-voltage switchgear and between switchgear sections. Manufactured from insulated conducting aluminium or copper bars MDY busbars are rigid and short-circuit resistant. In addition to full phase separation, the copper and aluminium busbars can also be protected from rain and mechanical damage using additional enclosures. Even with its open construction, ABB's MDY busducts can be used in demanding environments.

2. Schneider Electric (France)

The global electricals major has long advocated aluminium busbar’s advantages over copper busbar. Its Linergy line of brand offers a complete range of vertical, horizontal, insulated, rear/multistage, and multi-standard power busbars, while its Canalis brand represents a consistent, and comprehensive prefabricated busbar trunking system. Crafted ideally out of aluminium its easy installation makes Canalis busbar trunking system ideally suited for commercial and industrial buildings.

3. Siemens AG (Germany)

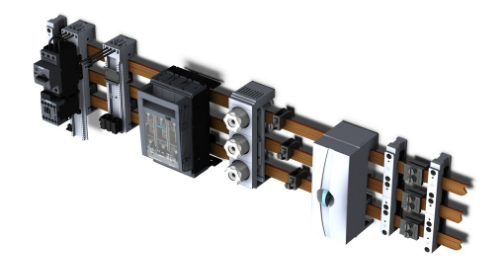

The use of busbar systems with their versatile rail-adaptable connection, switching and installation devices is an ideal and cost-effective electrotechnical enhancement of modern distribution boards due to their small footprint, compact design and quick assembly contacts. The mounting is implemented on longitudinal stays with spacing of 60 mm. The key benefits of Siemens' busbar are:

- Safe, space-saving, transparent and effective power distribution capability inside control cabinet

- Large range to suit a variety of current strength of up to 1,600 A

- Considerable cost reduction

- Readily mounted load feeders for reduced mounting time and costs

- Global applicability in control cabinets

{googleAdsense}

Siemens uses aluminium in its Sivacon 8PS products which provide efficient power transfer solutions in the increasingly complex area of building technology.

4. Eaton Corporation plc (Ireland)

Power Xpert® Busbar systems from Eaton are ideally suited for projects where flexibility and reliability are key to success. The busbar systems complement the Irish company’s low voltage distribution equipment from packaged substations and LV distribution switchboards to a complete selection of fused switchgear, circuit breaker systems and motor control gear products. All ranges of Eaton's busbars come in two versions- and aluminium version and a copper version. The aluminium busbars comply fully with IEC 61439-6 and make perfect choice for a wide range of applications.

5. Legrand S.A. (France)

The French electrical company manufactures its busbars using aluminium or copper. Legrand aluminium busbars are made of C-section rails and provide great flexibility of use. Connection is carried without drilling, using special hammer head screws. Normally, circulation of high current in busbars leads to the induction of magnetic fields in the surrounding exposed metal conductive parts, but Legrand's busbars support on aluminium crosspieces which help prevent the formation of such magnetic fields.

Other prominent vendors who are expected to play a key role in global aluminium busbar market over the next five-year period include C&S Electric Company (India), Eaton Corporation plc (Ireland), Mersen S.A. (France), CHINT Electric Co. Ltd. (China), Rittal GMBH & CO. KG (Germany), TE Connectivity, and Power Products.

Asia-Pacific is currently the largest market for busbar, followed by Europe. The Asia-Pacific market is primarily driven by countries such as China, Japan, India, Australia, and Rest of Asia-Pacific. China, like in many other aluminium end use applications, is expected to dominate the busbar market, followed by Japan and India during the forecast period.

This news is also available on our App 'AlCircle News' Android | iOS