Arctus Aluminium pioneers inert anode smelting for a zero-carbon future

The global primary aluminium production in 2024 reached 72.7 million tonnes (approx.). With demand continuing to rise, it is expected that production will also further increase in the coming years, leading to more environmental challenges. As a result, in order to tackle or overcome these hurdles, it is essential to establish various sustainable initiatives that will help the industry fight against increased CO2 emissions.

Image Source: FreePik

Arctus Aluminium’s carbon free aluminium production

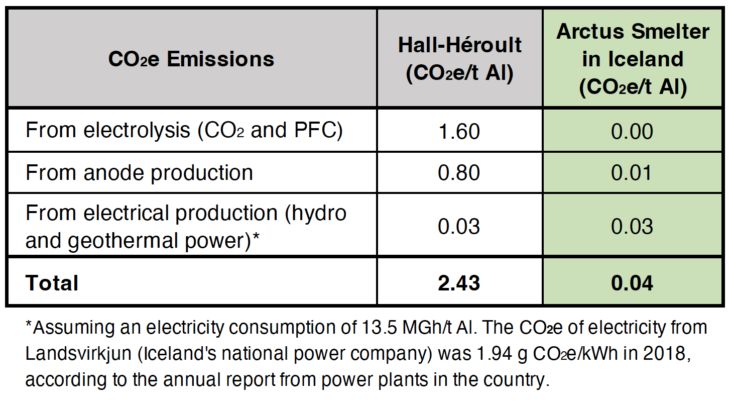

One such initiative has been developed by Iceland-based Arctus Aluminium. Unlike conventional methods, the company is developing a smelting technology that uses inert anodes, which generate oxygen instead of CO2. Additionally, Arctus Aluminium has joined the European REVEAL project, which seeks to transform energy storage by exploring aluminium's potential as a high-performance energy carrier.

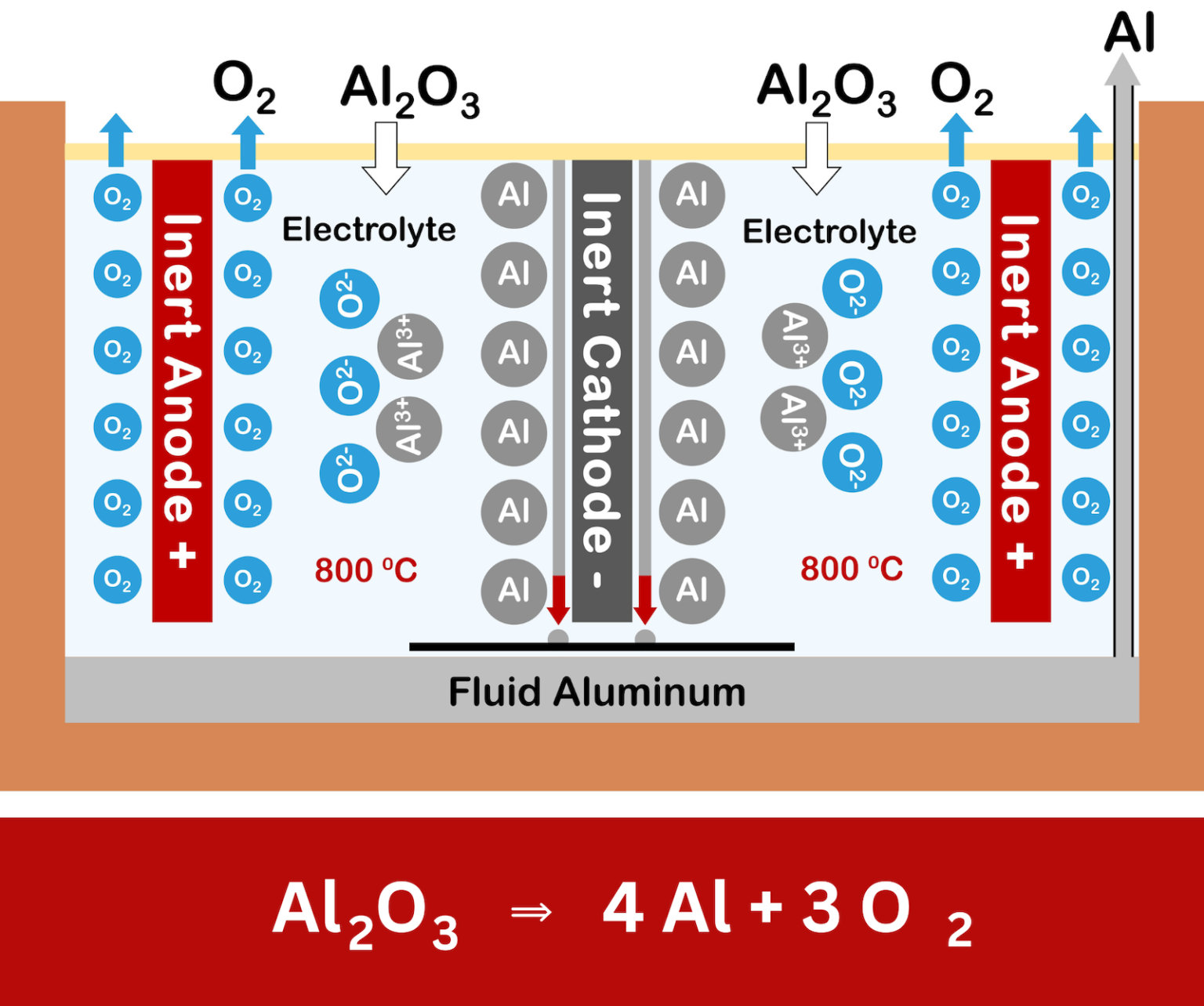

Arctus Aluminium is also advancing its own inert anode technology in collaboration with IceTec, an Icelandic research organisation, along with its industrial partners—Nordural, an Icelandic smelter, and Trimet Aluminium, Germany's largest primary aluminium producer. The company's approach centres on the Vertical Electrode Cell (VEC), which utilises vertical inert anodes and wettable inert cathodes. In the VEC system, the electrolyte operates at a relatively low temperature of 800°C (1,472°F). The inert anodes are composed of a non-consumable metal alloy, while the wettable inert cathodes consist of TiB2 plates.

These inert anode cells have successfully produced aluminium with a commercial purity of 99.8 per cent, emitting one tonne of oxygen per tonne of aluminium and eliminating direct CO2 emissions. The potential CO2 savings from this technology are significant. For example, in 2022, Iceland produced approximately 882,000 tonnes of aluminium. If fully implemented, this technology could prevent around 1.7 million tonnes of CO2 emissions—equivalent to nearly one-third of Iceland's total CO2 emissions.

Image Source: Light Metal Age

Image Source: Light Metal Age

Designed to enhance efficiency while reducing power consumption

The Arctus cells are designed to enhance efficiency while reducing power consumption by 20 per cent compared to conventional smelting. This is achieved through the low-temperature electrolyte and the strategic placement of the anodes and cathodes. Their vertical positioning exposes both sides of the electrodes, while the short anode-cathode distance (3–4 cm) further improves energy efficiency. Additionally, the cells support modular power feeding during peak hours, optimising electricity costs. These inert anode cells are also significantly more compact—one-third the size of a traditional Hall-Héroult cell—while maintaining the same aluminium output, cutting space requirements by 50 per cent. Arctus Aluminium estimates that this innovative design could reduce investment costs by 40 per cent and operational costs by 30 per cent.

Image Source: Light Metal Age

Partnership with Trimet

Following the successful completion of initial testing, Arctus partnered with Trimet to set up a demonstration facility at Trimet's Essen smelter in Germany. In August 2024, Trimet began commissioning 10 kA demonstration cells to evaluate the inert anode technology at an industrial scale. If the trials prove successful, the smelter plans to scale up the technology to 40 kA in 2025. The ultimate goal is to continue expanding the technology until full commercialisation is achieved by 2030.

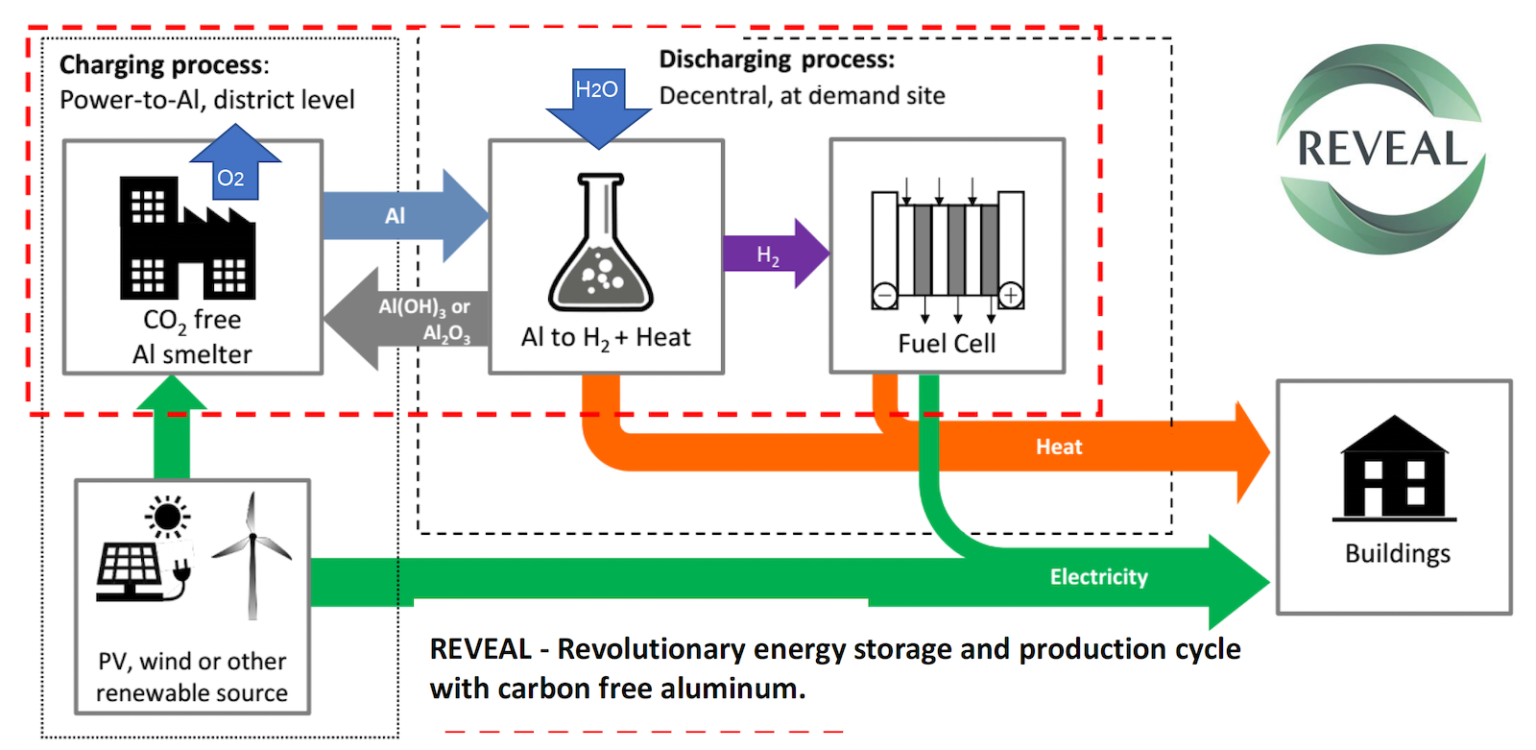

According to REVEAL, "The resulting aluminium acts as a compact, high-energy storage medium that can be utilised to generate on demand heat and hydrogen, or alternatively, heat and electricity, depending on the application. This approach offers key advantages, including a volumetric energy density more than twice that of [liquified natural gas], three times that of methanol, and over five times higher than liquid hydrogen."

The REVEAL project

The REVEAL project, involving Arctus, IceTec, SINTEF, and several other industrial and research partners, seeks to advance the concept of aluminium as an energy carrier even further. The goal is to develop a cost-effective solution for storing renewable energy over months or even longer. By integrating zero-carbon aluminium production—enabled by inert anodes—with renewable energy sources, the project aims to establish aluminium as a viable long-term energy storage medium.

Image Source: Light Metal Age

Image Source: Light Metal Age

The REVEAL project aims to create a closed material cycle, allowing aluminium used in the charging process to be repeatedly cycled between charging and discharging without replacing new alumina. In November 2024, the project reached a key milestone when the Eastern Switzerland University of Applied Sciences (OST) demonstrated that aluminium granules could achieve a bulk energy density of 15 MWh/m³. Repeated measurements have confirmed this high energy density, reinforcing aluminium's potential as an efficient energy carrier. Project partners continue to refine the technology by assessing its technical feasibility, cost-effectiveness, and environmental impact.

This news is also available on our App 'AlCircle News' Android | iOS

.jpg/0/0)

.gif/0/0)