BMW Group begins production of fuel cells for iX5 Hydrogen; stack housing manufactured at Landshut facility

As part of the company's hydrogen competence centre in Munich, BMW AG's Chairman of the Board of Management Oliver Zipse and Frank Weber, BMW AG's Member of the Board of Management for Development, inaugurated fuel cell system production on 31 August.

It marks the beginning of the global testing and demonstration of the BMW iX5 Hydrogen car for the end of this year. Adding fuel cells and high-performance batteries to the company's portfolio will add a unique form of the drive system for the premium segment to the company's portfolio. As a pioneer in this technology, BMW is pursuing a diversified transition to zero-emission mobility.

On 31st August 2022, Oliver Zipse stated in Munich, “As a versatile energy source, hydrogen has a key role on the road to climate neutrality. And it will also gain substantially in importance as far as personal mobility is concerned. We think hydrogen-powered vehicles are ideally placed technologically to fit alongside battery-electric vehicles and complete the electric mobility picture.”

“By commencing small-scale production of fuel cells today, we are demonstrating the technical maturity of this type of drive system and underscoring its potential for the future.”

Frank Weber said, "Our years of research and development work have enabled us to get the very most out of hydrogen technology."

"We have managed to more than double the continuous output of the second-generation fuel cell in the BMW iX5 Hydrogen, while weight and size have decreased drastically."

_0_0.jpg)

The BMW Group leads the way in developing hydrogen technology. According to the company, the next generation of its vehicles holds great promise, especially for countries in the Middle East.

Dr Hamid Haqparwar, Managing Director at BMW Group Middle East, said, “The in-house production of fuel cell systems marks an important milestone toward zero-emission mobility. In our view, hydrogen, one of the most efficient options for storing and transporting renewable energy, is the missing piece of the puzzle that can complement electromobility. It will contribute to achieving net zero carbon emissions by 2050 and play a major role as a fuel in this region.”

BMW will manufacture highly efficient fuel cell systems at its in-house competence centre for hydrogen. It generates a continuous output of 125 kW/170 hp and is a crucial element of the BMW iX5 Hydrogen. A fifth-generation BMW eDrive motor and a high-performance battery were explicitly designed for this vehicle to produce 275 kW/374 hp from its electric motor. With the small production run, the team incorporated the powerful drive system - including two hydrogen tanks, a fuel cell, and an electric motor - into the BMW X5.

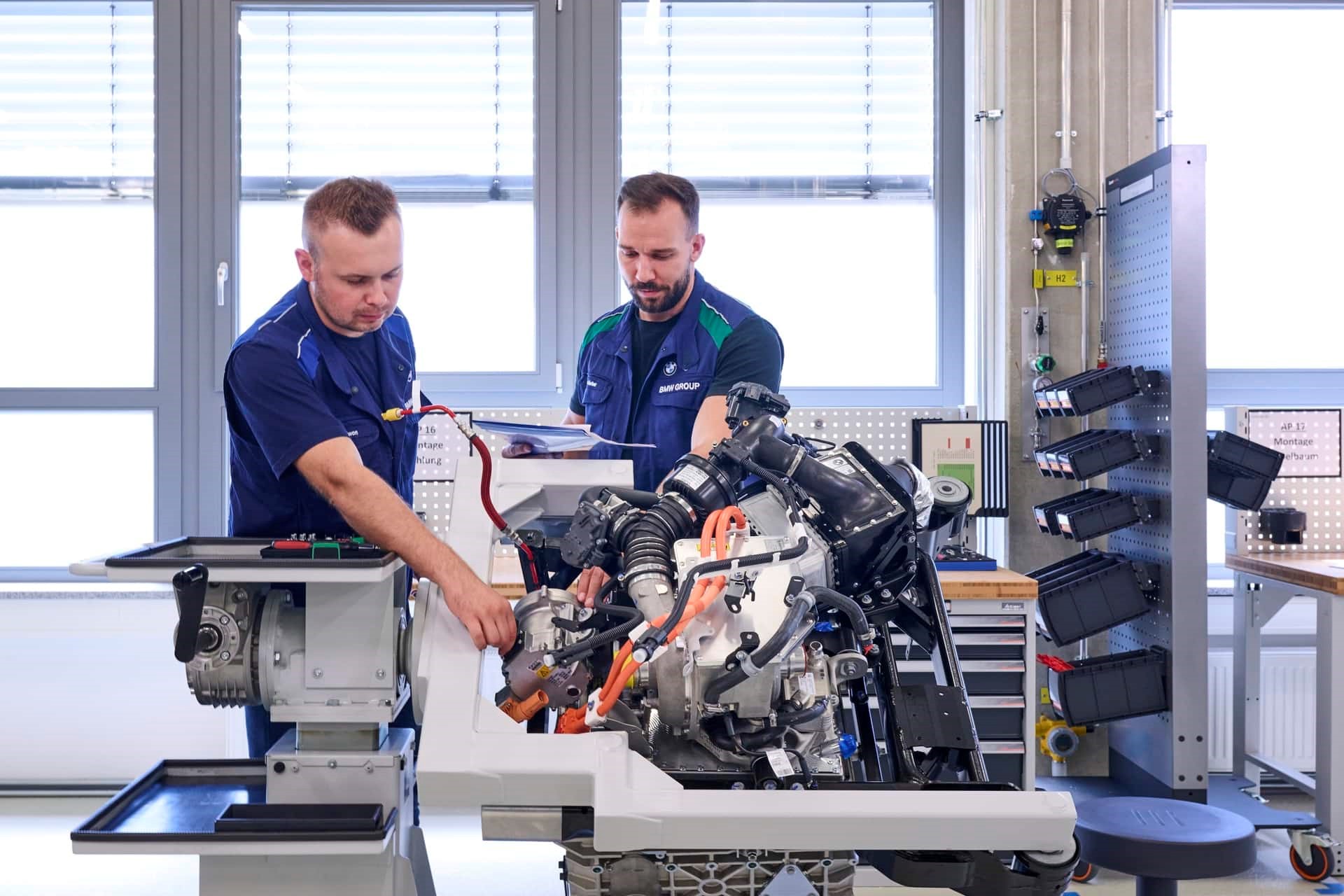

Fuel cells for the BMW iX5 Hydrogen are sourced from Toyota Motor Corporation. A trust has characterized their partnership for years, and they have collaborated on fuel cell drive systems since 2013. There are two main steps involved in the manufacture of fuel cell systems. It is first necessary to assemble the individual fuel cells into a stack of fuel cells. Once the other components have been fitted, a complete fuel cell system will be created.

The final assembly of the fuel cell stacks includes a voltage test along with extensive testing of the chemical reaction within the cells. Finally, all the different components are fitted together in the assembly area to produce the complete system.

The stacking of fuel cells is a fully automated process. A machine compresses the stack with a force of five tonnes after individual components have been inspected for damage.

However, using a sand casting technique, the stack housing is manufactured in the light metal foundry at BMW Group Plant Landshut. By this means, the molten aluminium is poured into a mould made from compacted sand mixed with resin in a procedure designed explicitly for this small-series vehicle.

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)