Pilot Energy, a leader in the clean energy transition, has partnered with South32 Worsley Alumina to conduct a feasibility study on carbon capture and storage (CCS) for its operations.

Launched in the quarter of January-March 2025, the study aims to evaluate the supply chain for capturing and storing up to ~700,000 tonnes of carbon dioxide annually. It will assess the onshore conditioning, transportation, and delivery of CO₂ from the alumina refining process’s flue gas streams to Pilot’s Cliff Head Carbon Storage project. However, the study is expected to be completed by Q3 2025.

Depending on the findings, the study could serve as a foundation for deeper commercial and technical discussions on Worsley Alumina's decarbonisation strategies.

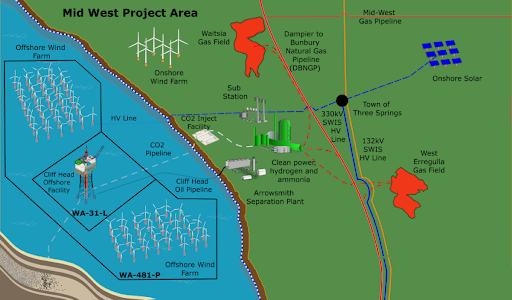

Additionally, the results will support Pilot's collaboration with other emitters in Western Australia to drive the Cliff Head Carbon Storage Project, the initial phase of the MWCEP.

Brad Lingo, Chairman of Pilot Energy, stated, "Pilot has been engaging with emitters in parallel with the technical development of the Cliff Head Carbon Storage Project."

"This study represents an important milestone in the development of the project and future supply chain infrastructure. We look forward to progressing the study with teams from South32, Chiyoda and KNCC."

To support the South32 study, Pilot has partnered with Chiyoda Corporation, a leading engineering firm specialising in onshore facilities, and Knutsen NYK Carbon Carriers, a key player in marine transportation.

What is carbon capture and storage?

Carbon Capture and Storage (CCS) is a crucial technology for reducing carbon dioxide (CO₂) emissions and combating global warming. This process involves three key steps: capturing CO₂ generated from power plants and industrial activities such as steel, cement, or aluminium production; transporting the captured CO₂; and securely storing it deep underground for permanent containment.

CCS is an emerging technology that supports the aluminium industry's decarbonisation efforts. It can significantly reduce carbon emissions from two key stages of aluminium production:

Aluminium Bahrain B.S.C. (Alba), the world's largest aluminium smelter outside China, has taken a significant step in advancing its ESG transformation by signing a Memorandum of Understanding (MoU) with Mitsubishi Heavy Industries EMEA Ltd. (MHI EMEA), a subsidiary of Mitsubishi Heavy Industries (MHI) Group. Inked on January 19, 2022, this collaboration aimed to explore innovative solutions for reducing Alba's carbon footprint.

Responses