Researchers develop low-cost aluminium formate (ALF) capable of hydrogen storage at non-cryogenic temperatures

According to the Oxford Institute for Energy Studies, the hydrogen industry faces challenges related to limited investments and an uncertain profit model. They recommend a strategic focus on hydrogen storage solutions to address these issues. Their proposal suggests that large-scale storage facilities should be established in proven salt caverns, primarily in countries such as Poland, Germany, and the United Kingdom. However, they anticipate less potential for such storage in southern European regions.

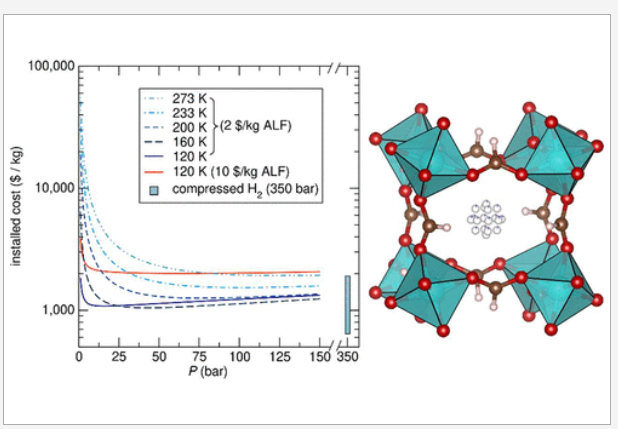

Researchers in the United States and Singapore have introduced a cost-effective solution called aluminium formate (ALF) for hydrogen storage. ALF can store significant quantities of hydrogen at temperatures at non-cryogenic levels, specifically at temperatures greater than 120 k (Kelvin), and it operates effectively at low pressures. Cooling to approximately -100°C is required to achieve optimal hydrogen storage with ALF.

This molecular sponge, comprising inexpensive aluminium and organic compounds, exhibits substantial potential for mass-market applications. It can be beneficial for storing fuel for industrial backup power generation.

ALF is competitively priced at just $2 per kilogram, a fraction of the community's targeted production cost of nickel-based metal-organic frameworks (MOFs), making it an appealing choice for developing safe and efficient hydrogen storage systems that support fuel cell technology.

Long-duration storage of hydrogen is necessary for coupling renewable H2 with stationary fuel cell power applications. In this work, aluminium formate (ALF), which adopts the ReO3-type structure, is shown to have remarkable H2 storage performance at non-cryogenic (>120 K) temperatures and low pressures. The most promising performance of ALF is found between 120 K and 160 K and at 10 bar to 20 bar.

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)