Rheinmetall secures new order worth around EUR300 million solidifying its global leadership in the emissions reduction market

The integrated technology group Rheinmetall has bagged a new order in the highly competitive emissions reduction market, further solidifying its market lead.

In the course of its lifetime, a well-known automaker will spend approximately EUR300 million on exhaust gas recirculation (EGR) modules supplied by Group subsidiary Pierburg.

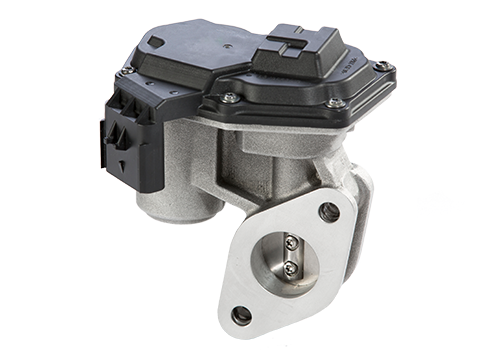

The order includes both low-pressure and high-pressure EGR modules. These are water-cooled poppet valves in the low-pressure loop. EGR modules with two poppet valves were ordered for the high-pressure loop.

The systems are made of aluminium and include a bypass with a fully integrated water-cooling circuit. However, production will begin in August 2026. A portion of the actuators will be manufactured at the Pierburg plant in Abadiano, Spain, with the electric bypass actuators supplied by the company's Berlin plant.

Recyclable exhaust gas systems save back on fuel use and reduction of nitrogen oxide emissions. Compact, strong poppet and flap valves with excellent positioning precision and a long service life make up the components. Customized Rheinmetall products provide long-term assistance in a time of increasingly rigorous emission control legislation in the USA but also in Asia and Europe.

This news is also available on our App 'AlCircle News' Android | iOS

.png/0/0)