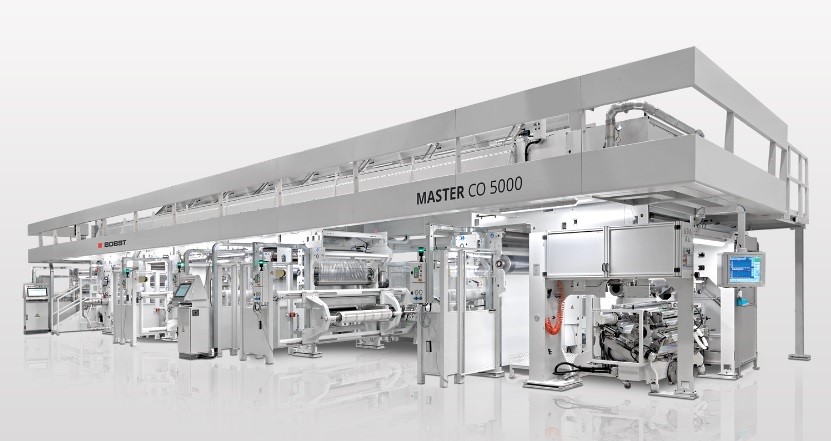

Symetal and BOBST are breaking boundaries in the aluminium foil coating and rolling sector with the MASTER CO 5000 coating machine, which was installed during the first quarter of 2022 in the former's production facility in Mandra, Greece.

The coater accomplishes Symetal's process quality expectations by augmenting the company's capacity from its existing weightage of 24,000 tonnes per annum.

Aluminium foil is a tender material; therefore, its transformation calls for high-end and elaborate technologies. The coating equipment is technically customised, requiring a close collaboration between the equipment manufacturer and the converter.

Symetal S.A. runs two ultra-modern production units in Greece; one in Oinofyta that manufactures aluminium foil rolls and the other in Mandra that masters in foil coating or paper lamination on a huge variety of converted and plain aluminium foil products from 6 to 100 microns.

ElvalHalcor S.A., the leading producer of copper and aluminium items for the emerging global market, is the mother company of Symetal, which specialises in aluminium products.

Symetal has an experience of more than four decades in the art of aluminium foil rolling and converting processes. The company is a strategic partner to well-known pharmaceutical, cigarette and food packaging enterprises.

"We operate in a highly competitive market and must continue investing and looking for the next innovations, focusing on production process optimisation and manufacturing of high value-added sustainable foil solutions", explained Mr Konstantinos Kontos, General Manager of Symetal. "We have collaborated closely with BOBST on a previous project, a highly customised tri-lacquering machine installed in 2015, which has been delivering the excellent output quality and process optimisation we were looking for. This is why we turned to BOBST again for our latest investment".

The new BOBST CO 5000 acquired by the company is a bi-lacquering machine, enhanced with different coating systems to comply with the definite needs of Symetal's customised applications. It has been optimised to coat both sides of the aluminium foil web, and it can collectively apply solvent or water-based coatings, along with heat sealings and protection primers.

"BOBST designs state-of-the-art equipment and understands the specific needs of our company. We appreciate the way we are able to collaborate on such customised projects. Together, we have developed solutions that enable us to create added value for our customers," Mr Kontos concluded.

Responses