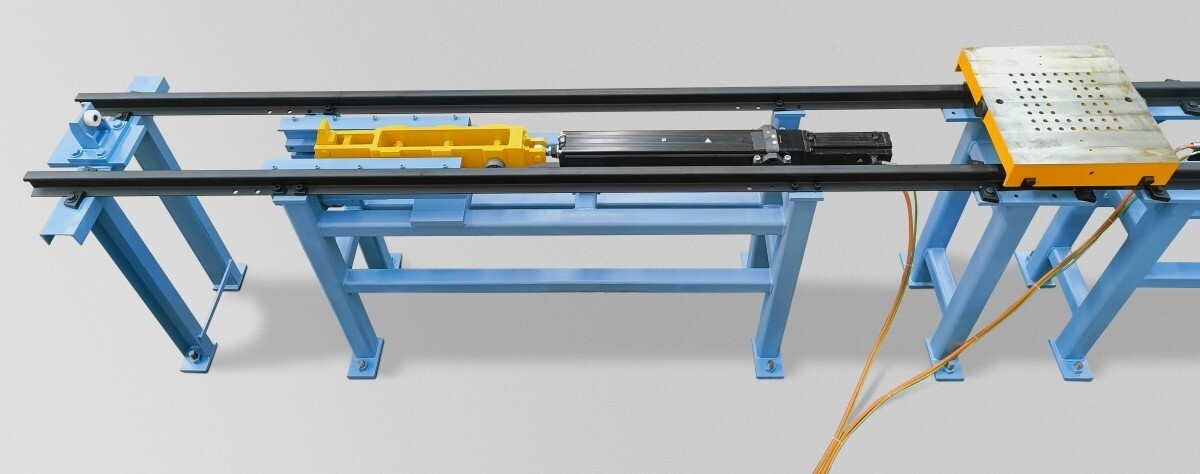

DISA, a Norican technology, has launched a new all-electric Automatic Mould Handling (AMH) system for its DISA MATCH moulding lines.

The new AMH replaces hydraulic power with state-of-the-art electric servo drives. These give very precise and smooth control of mould transportation, acceleration, deceleration, and velocity. Using electric drives cuts overall operating costs and boosts sustainability due to simpler maintenance, lower power consumption and no hydraulic oil.

“We’re introducing the latest technology to our new all-electric AMH for DISA MATCH,” says Kasper Paw Madsen, Vice President Portfolio Development at DISA. “Our new AMH features the latest electric servo drives that transport moulds gently yet very efficiently, and advance MATCH’s performance in multiple areas, from higher production rates and uptime to reduced maintenance and running costs.”

Electric servo motors bring multiple benefits

The new AMH, together with the DISA MATCH, is the perfect solution for foundries that want to upgrade their existing moulding line and increase capacity. The new servo drives transport moulds more gently to assure mould integrity and increase transport speed. Current and future DISA MATCH customers will enjoy the new AMH as it is a perfect fit for MATCH’s recently introduced Speed-Up Kits, which raise its maximum moulding speed to 210 uncored moulds per hour.

“The new AMH cuts operating costs because it uses less energy and requires less frequent maintenance,” explains Lars Hjelm, Global Product Manager for Moulding at DISA.

“With lower energy consumption, it’s more sustainable, plus there’s no oil to change and dispose of. You get a cleaner and quieter working environment, too.”

Capture valuable AMH data in Monitizer

The new AMH is simpler to install, while its more compact motors fit neatly under the ends of the conveyors. With a smaller overall footprint, it can fit in a smaller area or cool moulds for longer within the same floor space. That makes it ideal for space-constrained foundries.

Real-time data from the electric drives can be fed to IIoT systems like Monitizer for monitoring, analysis, predictive maintenance, and other applications. For example, variations in motor metrics like drive load can give early warning of emerging problems.

“DISA has already sold more than 10 new AMHs in North America alone, including an all-electrical AMH on Gamma Foundries’ DISA MATCH 20/24 in Richmond, Canada,” says Bo Wolff Haugbølle, Vice President OEM Sales at DISA. “The first will be installed later in 2025. We and our customers are very excited about the benefits of taking mould handling in this direction, and we look forward to seeing the new AMH in action very soon.”

“The precise control provided by servo technology allows for smoother accelerations and decelerations, ultimately boosting our line speeds and overall efficiency,” says Andrew Iannettoni, Foundry Technical Manager at Ford Meter Box. “Choosing an all-electric AMH could potentially reduce our insurance premiums since insurers prefer equipment without hydraulics, and we expect to see a decrease in power consumption by eliminating the constant operation of hydraulic pumps.”

Visit DISA at CastExpo on April 12-15th at Booth 1936 to see the E-Drive ball screw and discuss the advantages for your foundry.

DISA, a Norican Group technology, develops and manufactures a complete range of metal casting production solutions for the ferrous and non-ferrous foundry industries. Headquartered in Taastrup, Denmark, with a North American facility based in LaGrange, Georgia, DISA is the world-leading supplier of complete foundry solutions and services, as well as state-of-the-art green sand moulding equipment.

The use of aluminium has soared in recent years due to its lightweight in automotive, the rise of e-mobility, advances in 5G technology, and growing societal demands for improved recyclability and widespread rejection of plastics.

Note: This Press Release has been issued by DISA and has been published by AL Circle in its original form with minor modification.

Responses