Rio Tinto, Comptech collaborate to deliver a new generation of aluminium alloys for use in advanced technologies

The global aluminium giant, Rio Tinto partnering with aluminium semi-solid castings solution provider Comptech to drive in a new generation of aluminium alloys to the market towards the usage in advanced technologies such as electric vehicles and 5G antennas.

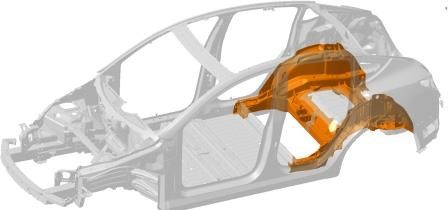

The metallurgical experts of Rio Tinto have designed the alloys for the semi-solid Rheocasting process offered by Comptech, to match the requirements of producing large, specialised single-piece designs, known as giga-casting.

The alloys offer high strength, electrical and thermal conductivity properties, while Rheocasting allows fast, low-cost production of advanced lightweight designs. The products are currently undergoing qualification with automakers in Europe.

Tolga Egrilmezer, Vice President of Sales and Marketing Aluminium, Rio Tinto, said: “Through this partnership, we are delivering a new range of specialised alloys designed to deliver high performance, lower-cost solutions for advanced applications like electric vehicles and 5G antennas. This is an area of emerging demand where our industry-leading research and development capability allows us to deliver products that meet the specific needs of manufacturers and end customers.”

Per Jansson, Group CEO and owner, Comptech said: “We are in the capacity ramp up for the next generation of advanced technologies across sectors such as automotive and communications, and our customers, both foundries and OEM´s will need the development of more advanced parts. This partnership positions us to offer customers the combined advantages of our casting process expertise and Rio Tinto’s technical strength and preferred alloys suite.”

This news is also available on our App 'AlCircle News' Android | iOS